PRODUCT FEATURES

Electric Rivet Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Electric Rivet Machine: Everything You Need to Know

When it comes to electric rivet machines, there are a lot of important factors to consider. What’s the right machine for your needs? How much guidance do you need in order to use it?

Electric rivet machines are electric riveting machines. They are designed to be used on electric-powered motors, either in a garage or at work. The electric motor is usually mounted onto a metal frame and has several gears attached to it, including the main gear and an auxiliary gearbox.

Are you in the market for an electric rivet machine? If so, you’re likely trying to decide which machine is right for your needs. In this blog post, we’ll discuss the different types of electric rivet machines and what each one is best used for. Keep reading to learn more!

Table of contents

1

What Is an Electric Rivet Machine

An electric rivet machine is a tool that is used to fasten two pieces of metal together by driving a rivet through them. Rivets are typically made of copper, aluminum, or steel. They can be either solid or tubular. Solid rivets are more common, but tubular rivets are more durable.

An electric rivet or electric cordless rivet machine works by driving a rivet through two pieces of metal. The electric current from the machine passes through the rivet and melts it, causing it to expand and tighten the two pieces of metal together.

An electric rivet tool is used in many different applications or depending on your settings. It can be used as tools for rivets or to repair broken objects, such as furniture or automobiles. It can also be used for construction projects for quality.

2

How Does an Electric Rivet Machine Work

An electric riveting tool or machine is a device that uses electric current to join two pieces of metal together. The electric current passes through a small metal electrode called a rivet, which causes the metal to heat up and merge with the other piece of metal.

This process is known as welding, and it creates a strong bond that is resistant to wear and tear.

The electric steel rivet gun is used to join a variety of metal components together, including car parts, machinery, and construction materials. They are a popular choice for industrial applications because they produce strong welds that are resistant to corrosion and wear.

3

Different Types of Electric Rivet Machines

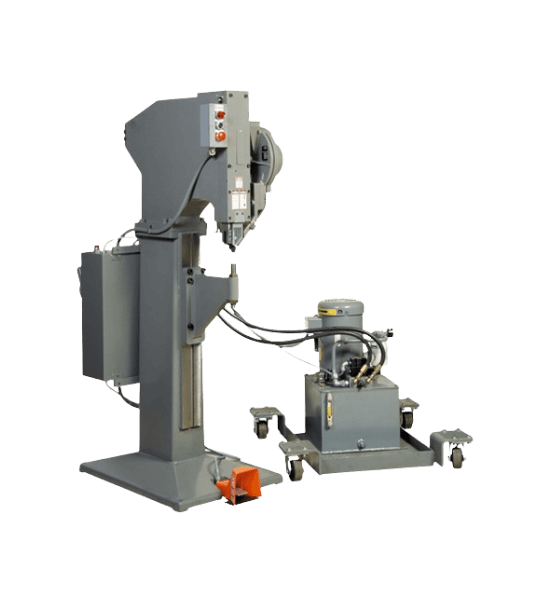

There are 3 main types of electric rivet machines: pneumatic, battery-powered, and electric.

Pneumatic Electric Rivet Machine

The pneumatic electric rivet machine is the most common type. It uses compressed air to power the riveting process. This type is best for use in a workshop or factory setting, as it is large and heavy.

Battery-Powered Electric Rivet Machine

The battery-operated hand rivet machine is the most portable type. It is small and lightweight, making it easy to move around. This type is best for use on the go or in tight spaces.

Electric Rivet Machine

The electric rivet machine is the most recent type of electric rivet machine. It is powered by electricity and does not require any compressed air or batteries. This type is best for use in a home setting.

The electric rivet machine is the most recent type of electric rivet machine other than the gas rivet gun. It is powered by electricity and does not require any compressed air or batteries. This type is best for use in a home setting.

Which electric rivet machine is right for you depends on your needs and preferences. Consider the size, weight, and portability of each type before making a decision.

4

Cost of an Electric Rivet Machine

The cost of an electric rivet machine and rivet kits can vary depending on the brand, the power of the machine, and other factors. Generally, electric rivet machines are more expensive than manual rivet machines.

However, electric rivet machines are much faster and easier to use, so they can save you a lot of time and effort in the long run.

Below are the approximate prices of electric rivet machines:

- Pneumatic Electric Rivet Machine: $200 – $600

- Battery-Powered Electric Rivet Machine: $100 – $300

- Electric Rivet Machine: $200 – $500

These are just estimated prices, so they may not be accurate for your specific electric rivet machine. Be sure to check the manufacturer’s website or contact them directly for a more exact price quote.

If you’re looking for an electric rivet machine, be sure to do your research and find the best one for your needs. You can find a variety of electric rivet machines on our website at Riveth. We offer electric rivet machines at a range of prices, so you’re sure to find one that suits your needs.

5

Benefits of Using an Electric Rivet Machine

An electric rivet machine is a great tool to have in any shop. There are many benefits of using one of these machines, including:

Quick and Easy Assembly

An electric rivet machine can help you quickly and easily assemble projects. The machine rivets the parts together quickly and efficiently, so you can get your project done in no time. Additionally, an electric rivet tool is easy to use, making them a great choice for beginners or those who are not familiar with using tools.

Increased Strength

Having an electric rivet machine can help increase the strength of your project. The electric rivet machine ensures that the rivets are properly placed and fastened, which helps make your final product stronger than it would be with hand-riveting.

Increased Efficiency

An electric rivet machine also helps increase efficiency in your shop. These machines attach rivets quickly and easily, so you can move on to the next step in your project with ease.

Additionally, electric rivet machines require little maintenance, meaning you can spend more time working on your projects and less time maintaining your tools.

Versatility

An electric rivet machine is versatile. These machines can be used on a variety of projects, from aircraft assembly to building boats and more. With electric rivet machines’ versatility, these tools are great for anyone who works with wood or other materials that use rivets to hold the pieces together.

Durability

Electric rivet machines are durable. These machines last for a long time and can be used on many projects, making them a great investment for any shop. Additionally, electric rivet machines require little maintenance and upkeep, meaning they will continue to work well in your shop for years to come.

Safety

An electric rivet machine is also a safe choice for your shop. These machines are easy to use and come with safety features that help keep you safe while you work. With an electric rivet machine, you can feel confident that you are using a tool that is both efficient and safe.

When it comes to choosing the right tools for your shop, electric rivet machines are a smart choice. These electric tools help increase efficiency and safety in the workplace while providing you with an easy way to attach rivets.

If you’re looking for electric rivet machines, browse our selection of electric tools at Riveth. We offer a variety of electric rivet machines as well as other electric tools to help you get the job done in your shop.

6

How To Choose the Right Electric Rivet Machine for Your Needs

When it comes to electric rivet machines, there are a lot of options to choose from. This can make it difficult to determine which machine is right for your needs. In this section, we will discuss some factors you should consider when choosing an electric rivet machine.

Capacity

When choosing an electric rivet machine, capacity is one of the most important factors to consider. The machine’s capacity refers to the size of rivets that the machine can accommodate. If you will be using a variety of different sizes of rivets or long rivets, you will need a machine with a variable capacity.

Power

Another important factor to consider when choosing an electric rivet machine is power. The amount of power the machine has will determine the size and type of rivets it can use. If you will be using large or heavy-duty rivets, you will need a machine with more power.

Speed

The speed at which the electric rivet machine operates can also be important. Some electric rivet machines operate very fast, while others have a slower operating speed. If you will be using large or heavy-duty rivets, you will need a faster machine so that it can apply them properly.

Based on these factors, you should be able to find the perfect electric rivet machine for your needs.

7

3 Tips on How To Use an Electric Rivet Machine Safely and Effectively

When using an electric rivet machine, there are a few things you can do to ensure safe and effective use. Here are a few tips:

#1 Rivets Should Be Appropriate in Size

The rivets you use should be appropriate in size for the hole you are trying to fill. If they are too big, they will not fit and if they are too small, they may not hold the rivet in place effectively.

#2 Make Sure the Rivet is in Place Correctly

Once you have put the rivet through the hole, make sure it is in place correctly before squeezing the handles together. If it is not in the correct position, you may end up with a crooked rivet.

#3 Check the Rivet for Wear and Tear

Once you have squeezed the handles together, check the rivet for any wear and tear. If it is damaged in any way, do not use it and replace it with a new one. Damaged rivets may not be effective in holding the object together.

Following these tips will help ensure the safe and effective use of your electric rivet machine. Thanks for reading!

If you’re looking to buy an electric rivet gun, be sure to check out our selection at Riveth! We have a variety of guns available, so you can find the perfect one for you and your project!

8

5 Tips for Maintaining Your Electric Rivet Machine Over Time

When maintaining your electric rivet machine, always be sure to keep the following in mind:

| No. | Tips |

|---|---|

| 1 | Keep Your Electric Rivet Machine Clean |

| 2 | Make Sure to Lubricate Your Electric Rivet Machine |

| 3 | Check the Electric Rivet Machine’s Cord and Plug |

| 4 | Be Sure To Oil Your Electric Rivet Machine Regularly |

| 3 | Be Careful Not To Overload Your Electric Rivet Machine |

#1 Keep Your Electric Rivet Machine Clean

One of the simplest ways to keep your electric rivet machine running smoothly is to clean it regularly. Make sure to remove any built-up debris or residue from the unit’s moving parts. This will help ensure that the machine runs efficiently and doesn’t overheat.

#2 Make Sure to Lubricate Your Electric Rivet Machine

Another simple way to keep your electric rivet machine running smoothly is by making sure it’s always properly lubricated. You can do this by applying a small amount of oil to the electric rivet machine’s moving parts, every few months or so. This will also help keep the electric rivet machine cool.

#3 Check the Electric Rivet Machine’s Cord and Plug

It’s important to always check the electric rivet machine’s cord and plug for any signs of wear and tear. If you notice that either is damaged in any way, be sure to replace them immediately. Damaged cords or plugs can pose a serious safety hazard.

#4 Be Sure To Oil Your Electric Rivet Machine Regularly

One of the best ways to keep your electric rivet machine running smoothly is by oiling it regularly. You can do this by applying a small amount of oil to the electric rivet machine’s moving parts, every few months or so. This will help keep the electric rivet machine cool and lubricated.

#5 Be Careful Not To Overload Your Electric Rivet Machine

It’s important to be careful not to overload your electric rivet machine. If you try to use the electric rivet machine for tasks that are too heavy or strenuous, it could result in damage to the unit. Always make sure to read the electric rivet machine’s owner’s manual before using it, to ensure that you’re using it correctly.

9

Conclusion

Rivets are used in a variety of applications, from industrial to automotive. They’re also an integral part of the construction process. Electric rivet machines are a valuable tool that’s easy to use for anyone. They also offer loads of benefits compared to manual tools.

If you need something powerful and reliable, electric riveters will help you get the job done quickly and efficiently – with less effort. Contact us for electric rivet machines, or electric tools and equipment. We’re here to help you!

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.