PRODUCT FEATURES

Foot Press Rivet Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us at [email protected]

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

BUYER’S GUIDE

Foot Press Rivet Machine

The Foot Press Rivet Machine is perfect for a wide range of applications, from home repairs to industrial projects. This heavy-duty press is made of durable steel and aluminum, with a foot pedal for hands-free operation.

Foot Press Rivet Machine is the perfect way to quickly and easily rivet metal parts together. The foot press is operated by your foot, so you can easily apply pressure while keeping both hands free. This makes it the perfect tool for any workshop or garage.

Table of contents

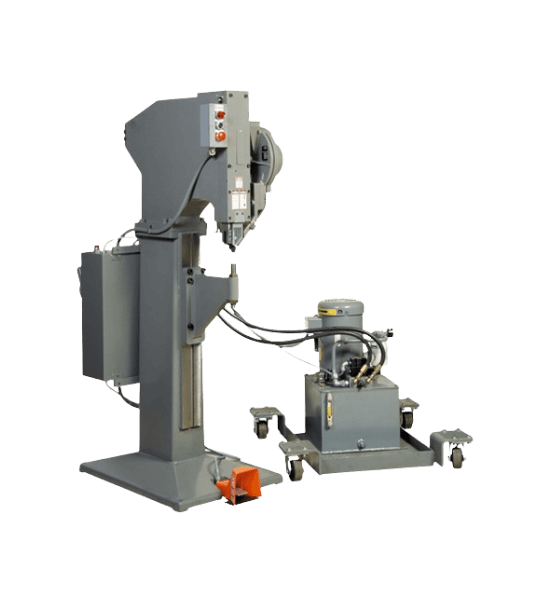

1. Foot Press Rivet Machine Definition

A foot operated rivet press is a type of riveting machine which uses a Foot pedal to activate the machine. The Foot pedal is used to provide power to the ram, which in turn drives the rivet into the workpiece. They are commonly used in manufacturing and construction applications.

It is a type of machine used to join two pieces of metal together by driving a rivet through the metal. It is powered by your feet, which gives you more power and control than you would have with a traditional rivet press.

They are available in a variety of sizes, so it’s important to choose the right size for your needs. They can be used to join a variety of materials, including aluminum, steel, and plastic.

Grommet foot press is easy to use – just place the materials to be joined in the clamps, apply pressure to the foot pedal, and release the pedal when the rivet is in place.

2. Foot Press Rivet Machine Benefits Over Traditional Rivet Presses

When it comes to riveting, there are a few different types of rivet presses that are available on the market. Rivet foot press is becoming more and more popular due to the number of benefits that they offer over traditional rivet presses.

Some of the key benefits include:

Higher Production Rates

Foot operated rivet presses can achieve higher production rates than traditional rivet presses because they are operated by foot. This allows for operators to maintain a consistent speed and rhythm, which can lead to increased efficiency and faster production times.

Safer to Operate

Another key benefit of foot operated rivet presses is that they are safer to operate than traditional rivet presses. Foot operated rivet presses are typically smaller and lighter in weight, which makes them easier to handle. They are also less likely to cause injuries because they are operated on by foot.

Less Maintenance

Foot operated rivet presses are typically less maintenance-intensive than traditional rivet presses are due to two main reasons. Foot operated rivet presses don’t require an electrical power source, which makes them much easier to maintain because no electricity is needed.

Also, there is no hydraulics involved in the operation of the foot pedal, which means that there are fewer components on the machine that can break.

User Friendly

Foot operated rivet presses are generally more user-friendly than traditional rivet presses. Foot press machine typically achieves higher production rates and don’t require as much setup time as traditional rivet presses do because of their simpler design.

Overall, kick press machine is quickly becoming popular in the riveting industry due to the number of benefits that they offer over traditional rivet presses.

3. Process to Use a Foot Press Rivet Machine

A rivet press is a handy tool for quickly and easily installing rivets. There are a variety of different types of rivet presses available, each with its own specific set of instructions.

The process for using a foot operated rivet press is as follows:

| No. | Steps |

|---|---|

| 1 | Prepare the Material |

| 2 | Align Bars and Insert Rivet |

| 3 | Adjust Rivet Diameter |

| 4 | Foot Pedal Operation |

Step#1 Prepare the Material

While rivets are installed through 3-dimensional materials, the process for riveting is virtually identical. Materials must be clean and dry before beginning. Remove burrs by filing any non-flush edges smooth.

While welding will not impact a metal’s ability to be riveted, it can cause distortion which makes it difficult to correctly place rivets.

Step#2 Align Bars and Insert Rivet

Place the material on a table or workbench with the side to be riveted facing up (damage cannot occur if this is done correctly). Place one bar inside each of the holes in the press plate, making sure that they are flush at both ends. Insert the rivet through the holes in the bars.

Step#3 Adjust Rivet Diameter

For correct installation, the correct diameter of rivets must be used. If a different size is used, damage to the press will occur.

Step#4 Foot Pedal Operation

With the material between the anvil and press plate, shut the handle of the press to hold it in place. The foot pedal is depressed, this causes a downward motion which drives the press prongs into the rivet and through your material.

This also moves the two bars apart so that you can remove your completed product from the press. Foot pedal released, anvil returns to its original position under spring tension. Press can be opened allowing you to remove parts from the press.

The foot pedal can be depressed again and the process is repeated until all parts are completed. This kick press is relatively simple to use and can be mastered in a short amount of time.

Just like that, you are ready to go on to the next project, install another rivet using the same procedure. Foot operated rivet presses are an invaluable tool for anyone who does any kind of metalworking or repair work regularly.

If you have never used a foot press machine before, follow these instructions and in no time you will be a pro.

4. Types of Materials Can Be Riveted With a Foot Press Rivet Machine

When it comes to riveting, there are a few different types of materials that can be used. In most cases, the material will be either a sheet or a tube. However, some materials can be riveted together using a foot operated rivet press.

Some of the common materials that can be riveted using this type of press include:

Aluminum

Aluminum is a material that is frequently used in both commercial and residential projects. It’s also an ideal candidate for riveting with a foot operated rivet press.

The reason it works so well is that aluminum has a low shear strength, which means it doesn’t take much force to cut through the material. This will make working with thick pieces of aluminum a lot easier.

Stainless Steel

Stainless steel is another material that can be riveted using this type of press. However, it’s not quite as ideal as aluminum because stainless steel has a higher shear strength which means you’ll need to use more force.

The good news about stainless steel is that it’s much easier to cut than many other types of metals. So it’s very easy to cut holes in your stainless steel sheets for bolts.

However, stainless steel is more expensive than aluminum so if you don’t need it for structural support, then aluminum may be a better choice.

Copper

Copper is a material that can be riveted with a foot operated rivet press. While real copper can be very expensive, copper-plated steel is a lot cheaper and still has the same appearance as a sheet of copper. It’s also easier to work with because it only requires the same pressure needed for aluminum instead of stainless steel.

Brass

It’s also the only non-ferrous metal on this list, which means it won’t rust or corrode. However, it will still conduct electricity so you may want to avoid using brass in certain situations.

Titanium

This metal has extremely high strength and low weight, which makes it great for aerospace and automotive industries along with other projects involving metal. However, titanium requires more force than aluminum so the average homeowner probably won’t want to use this type of rivet press.

Each of these materials has its unique benefits and drawbacks. It is important to understand the differences between them before making a decision on which type of material to use.

5. Choosing the Right Size Foot Press Rivet Machine for Your Needs

When choosing a foot operated rivet press, it is important to select the right size for your needs. The size of the rivet press will affect its performance and how easy it is to use.

Here are some things to consider when choosing the right size rivet press:

The Thickness of the Material You Will Be Working With

The thickness of the material you will be working with is also important to consider when choosing a foot operated rivet press. If you will be working with very thick materials, you will need a larger rivet press that can generate more force. If you are working with thin materials, a smaller rivet press may be adequate.

The Strength of the Rivets You Will Be Using

Many rivets come in different sizes, with larger rivets requiring more power to install than smaller rivets. Foot operated rivet presses are available in five, 10, 15, and 20-ton models based on the maximum load per handle stroke of each unit.

Floor Space Available for the Rivet Press

When choosing a foot operated rivet press, it is important to consider how much floor space you have available for it. The size of the rivet press will affect its performance and how easy it is to use.

By choosing a foot operated rivet press that matches your material thickness, rivet strength, and amount of available floor space, you can ensure an efficient and productive experience using this tool.

6. Where to Buy a Foot Press Rivet Machine For Sale

If you’re in the market for a Foot Operated Rivet Press, there are a few reputable places to buy them. Check out these options:

Riveth

Riveth is one of the most manufacturers in China. They are the supplier of Foot Operated Rivet Presses. Foot Operated Rivet Press can be made of stainless steel or common metals, like carbon steel. If you want to see more Foot Operated Rivet Presses, please visit riveth.com!

eBay

eBay is a great place to find a Foot Operated Rivet Press, as there are a variety of sellers who offer them. You can typically find good deals on Foot Operated Rivet Presses on eBay, and the process of buying one is relatively simple.

Amazon

Amazon also offers Foot Operated Rivet Presses for sale, and you can generally find a wide variety of models and brands to choose from. Amazon also offers free shipping on some Foot Operated Rivet Presses, which can be a big saving if you’re buying one online.

Craigslist

Craigslist is a good way to find Foot Operated Rivet Presses, as well as other miscellaneous tools and press machines. Many people selling Foot Operated Rivet Presses on Craigslist offer local pick-up only, but you can always search ” Foot Operated Rivet Press shipping” if you want to buy one online.

Industrial Suppliers

Industrial supply stores are a good place to find Foot Operated Rivet Presses, as they typically offer many different types of tools for sale. Foot Operated Rivet Presses can usually be found at local industrial supply stores, and it’s also possible to order them online.

Local Machine Shops

Many machinists and metalworkers have Foot Operated Rivet Presses in their shops, so check around your local area if you need a Foot Operated Rivet Press right away. If the company doesn’t have Foot Operated Rivet Presses on hand, they should be able to point you in the right direction.

Foot Operated Rivet Presses can typically be found at local hardware stores, but for a wider selection of Foot Operated Rivet Presses and faster delivery options, it’s a good idea to look online.

Foot Operated Rivet Presses can be used for a variety of purposes, and they come in different sizes and weights, so make sure you buy one that will work with your personal needs.

7. Foot Operated Rivet Press Maintenance

The Foot Operated Rivet Press is a manual machine and requires regular maintenance to ensure that it is in working order. The following are some tips for maintaining your Foot Operated Rivet Press:

Keep the Machine Clean and Free of Debris

Foot Operated Rivet Press foot pedals may get dirty over time, and some debris can build up in between the foot pedal and foot press. It is important to keep your Foot Operated Rivet Press foot pedal clean so that it operates properly.

Check for Loose Bolts Regularly

Rivets require a certain amount of force to function properly, and foot presses require a certain amount of torque as well. For foot pedals to operate properly, the nuts and bolts need to be fairly tight. If the foot pedal becomes loose or wobbly, it can affect how smoothly it operates.

Replace worn out parts as needed

Parts that are worn out, such as foot pedals and foot press plates, will need to be replaced. If you do not replace these parts when they get old or worn out, it can affect the performance of your foot press.

Lubricate Foot Pedal and Foot Press As Needed

If your foot pedal or foot press is not moving as smoothly as it used to, you may need to lubricate the foot pedal and foot press. Several different foot pedal lubricants can be applied for this purpose.

Maintenance of Foot Operated Rivet Press is not complicated and some simple steps can be taken to ensure it continues to serve you for many years.

8. Foot Operated Rivet Press Cost

The Foot Operated Rivet Press is a cost-effective riveting solution for both low and high-volume applications. It is a mechanical device that uses a foot pedal to manually activate the rivet.

This press can be used with a wide range of rivet sizes, making it an ideal option for a variety of projects. The Foot Operated Rivet Press is available in both manual and pneumatic models. The manual model is powered by a foot pedal, while the pneumatic model is powered by compressed air.

Both models are equally efficient, but the pneumatic model is slightly more expensive. The Foot Operated Rivet Press has a low cost of ownership and is an excellent investment for businesses that require riveting solutions.

The Foot Operated Rivet Press typically retails anywhere from $200 to $2,000 depending on the size and type. So make sure you look into Foot Operated Rivet Presses for your riveting needs. They are a durable and affordable option that is great for both high volume applications as well as low volume applications.

9. Tips for Using a Foot Press Rivet Machine Safely and Effectively

When using a foot operated rivet press, it is important to follow some basic safety guidelines to avoid potential injury. Some tips for safely using a foot operated rivet press include:

- Always wear safety goggles when operating the press.

- Keep hands and fingers clear of the moving parts of the press.

- Do not apply too much pressure when riveting, as this can cause the rivet to break or the material to deform.

- If the press seems to be struggling to drive the rivet through the material, stop and adjust the force setting accordingly.

- Do not use the press without all guards or shields properly in place.

- When finished, always release the foot pedal and allow the machine to come to a complete stop before moving away from it.

- Keep children and pets out of the area during use.

- Do not over-tighten screws of the press or anvils on which work is to be done.

- Never use a foot riveter that is missing parts or broken down.

- Never operate a foot riveter that has been dropped or damaged in any way, as this could result in injury.

- Keep the area around the press free of obstructions and combustible materials whenever possible.

- Always disconnect power before servicing machine components to avoid electric shock, especially when using the foot riveter near water.

- Always use the correct rivet for the job at hand press, as some types are not made to be driven with air tools.

- Keep your face and eyes away from possible danger points during riveting, such as the moving parts of the pneumatic press.

Overall, when using a foot powered riveter it is important to make sure safety is a priority. Following the tips above will help you to use a pneumatic rivet press safely.

10. Conclusion

Our rivet press is perfect for any workshop or garage. It’s made of durable steel and aluminum, with a foot pedal for hands-free operation. You’ll be able to quickly and easily rivet metal parts together with this press.

With this press, you can easily apply pressure while keeping both hands free. It comes with everything you need to get started right away, including an adjustable guide rail that allows you to set up different riveting applications quickly and easily.

Click here and get our best price on this amazing product!

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.