PRODUCT FEATURES

Industrial Rivet Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Industrial Rivet Machine

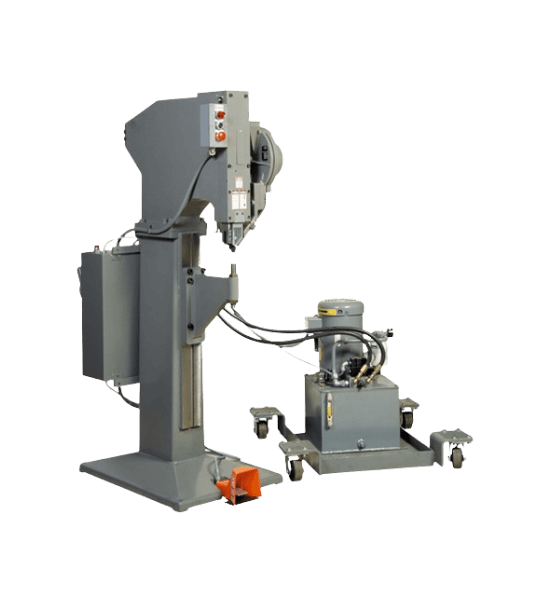

An industrial rivet machine is a professional-grade tool that is perfect for heavy-duty industrial applications. It features a powerful air motor that delivers 1,000 rivets per minute and has a long-lasting battery.

The industrial rivet machine is made from high-quality materials that are durable and lightweight. It also has a universal handle to provide a comfortable grip so you can do your work faster and more efficiently.

Table of contents

1. Industrial Rivet Machine Definition

An industrial rivet machine is a device that is used to join two pieces of metal together by driving a rivet through them. The rivet is inserted into a hole that is drilled in the metal, and then the machine is used to apply pressure to the rivet until it expands and locks the two pieces of metal together.

Many industrial rivet machines can be set up for manual use or automatic use. It is important to know which type of rivet machine is best suited for your industrial needs before buying one.

2. What Is an Industrial Rivet Machine and What Are Its Uses

An industrial rivet machine is a type of machine that is used for fastening two pieces of metal together. It is a common tool in industrial and manufacturing settings.

There are a few different types of industrial rivet machines, but they all work by using a rivet to join two pieces of metal together. Rivets come in a variety of different sizes and materials, so it is important to choose the right one for the job.

Below are the uses of the industrial rivet machine:

Used in Industrial Applications

One industrial rivet machine is used in industrial applications to make industrial metal furniture. Riveting two pieces of metal together creates a sturdy product that has few moving parts, allowing it to take more abuse than other types of products made from welded metal.

Used to Assemble Industrial Products

Rivets can also be used as a way to assemble industrial products. In this application, the rivet is placed in a hole that has been drilled into the metal pieces and then pressed into place to join them together.

This allows industrial manufacturers to produce their products more quickly because they don’t have to wait for glue or another type of adhesive to dry. Rivets also give industrial products more of a polished look because they are more aesthetically pleasing than other types of fasteners.

Used in Car Body Repairs

Industrial rivet machines can be used for car body repairs, which is commonly called industrial metal finishing. It’s often used to repair dents, but it can also be used to reattach a bumper or fix rust spots.

In industrial metal finishing, industrial rivet machines are used with industrial adhesives that have been warmed up, allowing them to dry faster and adhere better.

If you are looking for industrial rivet machines, contact us at Riveth. Riveth is a leading manufacturer of riveting machines and equipment in China. Riveth’s mission statement is to be the best Chinese manufacturer of riveting machines by adhering to high-quality standards that guarantee customer satisfaction.

We develop, create, and maintain dependable and cost-effective riveting solutions for a wide range of industries including automobile, motorcycle, aeronautical, hardware, and architectural.

3. How Does Rivet Machine Work

A rivet machine is a tool that is used to join two pieces of metal together. It does this by driving a rivet through the pieces and securing them in place.

Rivets are usually made out of metal, but they can also be made out of plastic or other materials. There are a few different types of rivet machines such as an automatic rivet machine, but they all work in basically the same way. The riveting machine consists of a frame, a die block, an anvil, and a ram.

Here’s how the rivet machine works:

The bottom piece of metal is placed into the die block with the rivet protruding through it. The ram then strikes down, driving the rivet down to create a permanent seal between the two pieces.

Since this entire process happens in one quick motion there are no tools needed to complete this task once you have your industrial riveting machine.

4. The Different Types of Rivet Machines Available on the Market

There are different types of rivet machines that are available on the market. The three most common types of rivet machines are pneumatic, electric, and manual rivet machines.

Pneumatic Rivet Machine

The pneumatic rivet machine is a type of rivet machine that uses compressed air to power the riveting process. This type of rivet machine is the most popular type of rivet machine and is used for industrial applications.

Electric Rivet Machine

The electric rivet machine is a type of rivet machine that uses electricity to power the riveting process. This type of rivet machine is often used in smaller applications because it is more portable than other types of rivet machines.

Manual Rivet Machine

The manual rivet machine is a type of rivet machine that uses human force to power the riveting process. This type of rivet machine is commonly used in industrial applications where electricity or compressed air are not readily available.

If you want to know more about industrial rivet machines, feel free to contact us at Riveth. We are looking forward to being in service for you shortly.

5. The Benefits of Using a Rivet Machine in Your Business

When it comes to industrial rivet machines, there are many benefits that businesses can enjoy. Here are some of the main benefits:

Increased Productivity

A rivet machine can help you to significantly increase your productivity. This is because it enables you to rivet multiple parts at once, which saves time.

Increased Quality

Using a rivet machine also helps to ensure that your products have a high level of quality. This is because the rivets are evenly distributed and create a strong joint.

Increased Efficiency

A rivet machine also helps to increase your efficiency, as you don’t have to spend time manually riveting parts together. This means that you can focus on other tasks and projects.

Reduced Costs

Rivet machines have also been known to help businesses reduce their costs, as they require less labor to run the industrial riveting machine. This is because you don’t need an operator for each industrial riveter unit you use.

6. How to Choose the Right Rivet Machine for Your Needs

When it comes to industrial rivet machines, there are a few key factors you need to keep in mind to choose the right one for your needs.

The Type of Rivets You’ll Be Using

The riveting machine that you need will depend upon the type of rivets you’ll be using. If you use blind rivets which are designed to sit partially within a material and fasten it together, then your industrial rivet machine will need to have adjustable or interchangeable modules so that the depth of penetration can be easily changed.

The Mass of the Material You’ll Be Riveting

Another factor to consider when choosing industrial rivet machines is the mass you need to be able to handle. If your industrial rivets machine doesn’t have enough power, it won’t be able to run smoothly and will chew through the material much faster than necessary.

Your industrial rivet machine should be able to handle heavy-duty industrial materials, especially if your riveting requires any speed which will increase the load.

The Quantity of Rivets You’ll Be Producing

If you need industrial rivet machines that can produce a ridiculously large amount of rivets, such as in an assembly line or high-production industrial setting, you’ll need industrial rivet machines that can handle high speeds and masses without giving out.

The Number of Components You Need to Rivet

If you intend for your industrial rivet machine to be an industrial riveter, then it should also be able to attach multiple components at one time. This will save you a ton of time and money compared to attaching each component one at a time.

Industrial rivet machines are not cheap, so if you’re on a budget it is advisable to start with a single industrial riveter that will handle the minimum amount of work that your company requires for now and then purchase additional industrial riveters as needed.

If you want to purchase industrial rivet machines for industrial or manufacturing purposes, contact us at Riveth. We pride ourselves on our customer service and dedication to providing the best industrial riveting product. We will be more than happy to help you choose industrial rivet machines for your needs.

7. The Cost of Industrial Rivet Machines and How to Get the Best Price

The cost of industrial rivet machines can range from a few hundred dollars to well over $10,000, depending on the type and size of the machine and the riveting machines manufacturers.

Below is the approximate cost of industrial rivet machines by types:

- Pneumatic Rivet Machine: $200 – $3,000

- Manual Rivet Machine: $1000 – $3,000

- Electric Rivet Machine: $1,500 – $15,000

When looking to get the best price on industrial rivet machines, be sure to shop around and compare prices. Also, be sure to ask the seller about any special deals or discounts they may be offering. Make sure to consider the shipping cost as well.

To get an exact quote and the best price on industrial rivet machines, just request a free quote from us at Riveth. We are one of the rivet machine manufacturers and we offer industrial rivet machines at the most affordable rates in the industry.

8. 5 Tips for Using a Rivet Machine Safely and Efficiently

When using a rivet machine, there are a few safety tips that you should keep in mind. Here are 5 tips for using a rivet machine safely and efficiently:

| No. | Tips |

|---|---|

| 1 | Always Wear Safety Goggles When Using a Rivet Machine |

| 2 | Make Sure the Rivet Machine Is Unplugged When Not in Use |

| 3 | Keep Your Hands and Fingers Clear of the Moving Parts of the Machine |

| 4 | Do Not Overload the Rivet Machine |

| 5 | If the Machine Starts To Smoke, Stop Using It and Unplug It Immediately |

#1 Always Wear Safety Goggles When Using a Rivet Machine

When using a rivet machine, you must always wear safety goggles. You never know if pieces of metal or material could fly into your eyes and cause damage to the eye area. By wearing safety goggles, you will be protecting your eyes from any possible damage.

#2 Make Sure the Rivet Machine Is Unplugged When Not in Use

When not using the rivet machine, it is important to make sure that you unplugged it. Never leave an industrial rivet machine plugged in when not in use as this could cause the wire to overheat and possibly electrocute or injure someone. When using a rivet machine, remember to always unplug it after every use.

#3 Keep Your Hands and Fingers Clear of the Moving Parts of the Machine

When using industrial rivet machines, you must keep your hands and fingers clear of the moving parts. Not only can they cause damage to your hands or fingers if they come into contact with them, but they could also cause serious injury if they get in between the moving part.

#4 Do Not Overload the Rivet Machine

Another important safety tip to keep in mind is that you should never overload a rivet machine. If you have too much on the industrial rivet machine, then it could cause it to malfunction or not work properly.

#5 If the Machine Starts To Smoke, Stop Using It and Unplug It Immediately

If for some reason, the industrial rivet machine starts to smoke or work incorrectly as you are using it, then you need to stop and unplug it right away. This could be a sign that something is wrong with the industrial rivet machine and that it needs to be properly repaired by trained professionals.

9. Final Words

The industrial rivet machine is perfect for heavy-duty applications. It’s made from high-quality materials that are durable and lightweight, so it can last in even the toughest environments. Plus, its universal handle provides a comfortable grip so you can do your work faster and more efficiently.

It’s not just an amazing product but also an incredible experience that will make your life easier every time you use it! Click here to purchase yours now at our Riveth online store!

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.