PRODUCT FEATURES

All Kinds of Rivet Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

All Kinds of Rivet Machine: What You Need to Know

There are different kinds of rivet machines on the market these days, and it can be tough to figure out which one is right for your business.

Rivet machines all have different features and functions, so you’ll need to do your research and find the right one for your business. You don’t want to buy a rivet machine that isn’t suitable for your needs, so it is important that you figure out all of the features before making a purchase.

In this blog post, we’ll take a look at the different types of rivet machines and what you need to know before making a purchase. We’ll also discuss some of the advantages of using a rivet machine in your business. So if you’re thinking about investing in a rivet machine, keep reading!

Table of contents

1. Semi Tubular Rivet Machine

Semi tubular rivets or rivet guns are used to install rivets together. It uses a semi-tubular rivet, which is a type of rivet that has a hollowed-out middle.

The rivet gun types are used because it is less likely to break than traditional drive rivets. Rivets are used in all kinds of manufacturing, job sites, and construction sites, from the aerospace industry to furniture building.

Advantages

- Very fast

- Very efficient

- Easy to use

- Handy

Disadvantages

- Loud

- Dangerous

If you want to know more about Semi Tubular Riveters and other types of pneumatic rivet gun machines, please contact us at Riveth. We manufacture all types of rivet guns, pneumatic rivet guns, and rivet tools at very competitive prices.

We’ll be glad to answer your queries and provide you with a full quotation on our products.

2. Screw Riveting Machine

A Screw Riveting Machine is a machine that is used to join two pieces of metal together by driving rivet nuts through the metal.

The screw is then turned so that the threads on the screw grab onto the metal and pull it tight. This creates a rivet that holds the two pieces of metal together.

The screw riveting machine is a type of all-purpose rivet machine that has several advantages and disadvantages.

Advantages

- Versatility

- High production rate

- Easy to set up

Disadvantages

- Expensive

- Lacks power compared to other riveters

3. Hollow Rivet Machine

Hollow Rivet Machines are tools used in riveting for installing two external concave grooves in the stationary hollow piercing tool and one or more external punch pins.

The head of the stationary piercing tool is clamped in a manner that allows rotation, and the movable piercing tools reciprocate into this rotating head.

The rivet is placed in the stationary hollow piercing tool and the punch pin(s) are forced into it, deforming the blind rivet so that its two legs grip the inside surfaces of the grooves.

Advantages

- Very fast and efficient

- Perfect for large-scale projects

Disadvantages

- Messy

- Problematic for flammable materials

4. Hinges Riveting Machine

Hinges riveting machines are tools used for riveting that are used specifically for riveting hinges. It is a specialized tool that makes the process of attaching hinges much easier and faster.

A hinges riveting machine is used by pulling a lever that forces the rivets through all three layers of material. The operator then flips a small switch to make all of the attachments simultaneously.

It can be used for all types of materials, from steel and aluminum to plastics and other metals. This type of equipment is commonly found in plants and assembly lines that manufacture hinges and blind rivets, as well as in automotive and aircraft factories.

Advantages

- The Hinges Riveting Machine is very efficient and can save you a lot of time.

- It is also very accurate, which means that the rivets will be placed in the right spot every time.

Disadvantages

- The machine can be a bit heavy and difficult to move around.

- It also requires a lot of maintenance, so you’ll need to keep it in good condition if you want it to last.

5. Double Head Riveting Machine

A double-head riveting machine is a type of riveting machine that uses two heads to rivet items together.

This type of machine is often used in manufacturing and automotive applications. The double-head riveting machine is also referred to as a multi-head riveting machine.

A double-head riveting machine works by using two heads that work together to secure an object in place. One head will hold the material in place while the other deforms the object to create a mechanical lock.

This is done by using a hydraulic press that uses air or liquid pressure to deform and hold the fastener in place.

A double-head riveting machine can be used with all different types of materials and all different types of rivets, including solid shank, semi-tubular, and fully-tubular rivets.

They are often used in manufacturing applications where a high level of accuracy is required. The double-head riveting machine can also be used for automotive applications, such as securing the body of a car.

Here’s a video on how double riveting machine’s used in door hinge manufacturing:

6. Dog Collar Rivet Machine

A Dog Collar Rivet Machine is a device that is used to fasten together the parts of a dog collar using rivets.

The rivets are inserted into the holes in the parts of the collar, and then the machine is used to apply pressure to the rivet, which causes it to expand and secure the parts of the collar together.

There are all kinds of rivet machines, including manual and electric versions.

There are pros and cons to using a Dog Collar Rivet Machine, here are some of those:

Advantages

- Fast

- Easy to use

- Secure

Disadvantages

- Expensive

- Difficult to use

7. Double Cap Rivet Press Machine

There are many types of riveting tools. The double cap rivet press machine is one of them. It is a tool that is used to join two pieces of metal together by driving a rivet through the pieces. There are different kinds of rivet machines, including single cap rivet machines and double cap rivet machines.

The double cap rivet machine is a type of rivet press machine that has two dies, or caps, that are used to clamp the rivet in place. This type of machine is often used in the automotive industry to join body panels together.

The double cap rivet machine is also sometimes referred to as a toggle press machine or a toggle rivet machine. The approximate price for a double cap rivet press machine is $5,000 to $7,000.

Advantages

- It can be used to join pieces of metal, including dissimilar materials like aluminum and steel.

- The two dies mean that two pieces of material can be joined at the same time.

- The machine is less expensive than a toggle-less rivet press machine or a pneumatic rivet press machine.

Disadvantages

- The machine cannot be used to join different types of metals together. This is not the machine for you if you are working with steel and brass, for example.

- The machine is more expensive than a single cap rivet press machine and other riveting tools types.

- After repeated use, the dies may require replacement, which means that the machine’s resale value will be low due to the high cost of replacing them.

8. Fan Riveting Machine

Fan riveting machines are a type of riveting machine that are used to join two pieces of metal together. They are often used in the automotive and aerospace industries. There are a few different types of fan riveting machines, including pneumatic, hydraulic, and electric.

Pneumatic fan riveting machines are the most common type of fan riveting machine. They use compressed air to power the riveting process. Hydraulic fan riveting machines use hydraulic pressure to power the riveting process. Electric fan riveting machines use electric current to power the riveting process.

The approximate price for a fan riveting machine is $5,000- $10,000.

Advantages

- Fan riveting machines are used to join together pieces of metal. They have a lot of strength and can join two pieces of metal with as much as 10,000 pounds of pressure as the other types of riveting machines.

- Fan riveting machines save a lot of time because they don’t require any type of welding or brazing.

- Fan riveting machines are easy to use and require very little training.

Disadvantages

- Fan riveting machines are large and heavy.

- They also require compressed air or hydraulic fluid to power them. If the compressed air or hydraulic fluid were to run out, then the fan riveting machine wouldn’t be able to function properly anymore.

- Another disadvantage is that they are very expensive pieces of machinery. They can cost upwards of $5,000- $10,000.

9. Mini Riveting Machine

A mini riveting machine is a small and handy tool that is used to join two pieces of metal together. It is a handheld device that uses a rivet to attach pieces of metal.

The mini riveting machine is a very versatile tool, and it can be used for a variety of purposes. Some of the most common applications for a mini riveting machine include:

- Joining two pieces of metal together

- Repairing a broken piece of metal

- Making jewelry

- Making small household projects

The approximate price of a mini riveting machine is $80-125.

Advantages

- It is very powerful, and it is able to do most projects with ease.

- It has an ergonomic design that makes it comfortable to use for long periods of time.

- It is easy to carry around, and it is light enough to be used by children.

- The price point of this tool is attractive, and it is affordable for most people.

Disadvantages

- The riveting capacity of this machine is small, and it can only handle ¼ inch rivets.

- The cylinder does not have a removable head, so it cannot be used to make larger pieces of metal art or jewelry.

- It takes practice to get used to using a riveting machine, and it is easy to make mistakes that ruin the project.

10. Number Plate Rivet Machine

A number plate rivet machine is a tool that is used to attach number plates to vehicles. It is a handheld device that has a small metal rivet at the end of it.

There is a number of plate rivet machines that can be used by hand or with a power tool. In most cases, the machine that is used will depend on the size of the job and whether it is being done professionally or just at home.

A professional would normally have a stronger machine to attach larger plates, while a smaller one may be all that is needed to attach a number plate at home. The approximate price for a machine can vary from $20 to $40.

Advantages

- Fast and easy to use.

- Can be used by hand or with a drill.

- Smaller machines are cheaper than larger ones.

Disadvantages

- Not as strong as larger machines.

- Doesn’t work on aluminum number plates.

11. Plastic Rivet Machine

A plastic rivet machine is a device used to join two pieces of plastic together by driving a rivet through the pieces. This tool is highly versatile and can be used to join pieces of plastic together for a variety of purposes.

Some common uses for a plastic rivet machine include joining two pieces of plastic together to make certain types of containers, shoes, furniture covers, electronics cases, etc. All you have to do is simply find out what size rivets are necessary for the pieces of plastic that you are joining together.

Most plastic rivet machines can be used by hand, with the exception of some larger ones. These machines are highly recommended for most types of plastic work done at home or in a professional setting. The price range for the plastic rivet machine is $50 to $100.

Advantages

- It is inexpensive.

- It does not take up a lot of space, making it ideal for home or professional use.

- It is highly versatile, allowing it to be used for many different applications.

Disadvantages

- The rivets can sometimes come apart when they are being pushed through the pieces of plastic. This is only an issue if the rivets are not being pushed through properly.

- It can be dangerous, so it should only be used by an adult with a steady hand.

12. Pipe Riveting Machine

A pipe riveting machine is a type of machine used to join two pieces of metal together by driving a rivet through them. This machine is specifically designed to penetrate through the metal and hold it tightly in place, which is why there are special rivets called blind rivet types that are required for this type of work.

Pipe riveting machines are commonly used in the manufacturing and construction industries to join metal pipes, plates, and other components together. They are typically powered by electricity or pneumatics and can range in size from small hand-held models to large industrial machines.

The approximate price range for a pipe riveting machine is between $5,000 and $30,000.

Advantages

- The machine can power through thick metal

- Fast process

- Can be used for welding as well as riveting

- Effective when joined with different types of metals

Disadvantages

- Highly-priced, making it difficult for some consumers to afford.

- Industrial versions are large and bulky.

- May require pneumatics in order to work.

13. Solid Rivet Machine

All kinds of solid rivets can be made by a solid riveting machine. The required metal pieces will be placed into the required place and then press to get all-around peeling off, which avoids secondary damage caused by hammering. All the metal pieces must be placed in a fixed position for avoiding shifting during operation.

This machine works by adjusting the gap of anvils, which determines the gap between rivets. All kinds of metal pieces can be fixed firmly by adjusting the gap. All kinds of solid rivet machines are easy to operate. The approximate price of a solid rivet machine is about $4000.

Advantages

- Improve productivity

- Low energy consumption

- No secondary damage

Disadvantages

- Expensive investment

- Need a great number of skilled operators

- Rivets of inconsistent sizes

14. Blind Rivet Machine

A blind rivet is a fastener that is installed without protruding on the outside of the joint and cannot be seen after installation, making it “blind”. The estimated cost of a blind rivet machine is around $1600.

Blind rivets are used in applications where the rivet head does not require paint or plating after installation, and/or in locations where access to the other side is difficult. They are often used when attaching thin pieces of sheet metal because they reduce or eliminate damage caused by punching a hole in the material with a drilled hole.

Advantages

- Reduce the cost of labor and material resources

- Improve productivity

- Rivets of the same size

Disadvantages

- Decrease aesthetics of project due to appearance of protruding rivets at joints

- Increased risk of dropping metallic pieces into machinery or assembly area, resulting in costly damage or injuries

- Material damage may occur during the installation process for damaged peeling off process

15. Eyelet Riveting Machine

An eyelet riveting machine is a specialized type of rivet machine used for installing eyelets in fabric or leather. Eyelets are typically used for reinforcing weak spots in the material, such as where a belt buckle or strap attaches to a piece of clothing.

An eyelet riveting machine is a type of rivet tool that drills and countersinks an opening in metal, plastic, or wood to form an oval-shaped blind hole for the installation of an internal (blind) rivet such as a solid or semi-tubular rivet.

This machine is typically used in the footwear, garment, belt & bag industry, and its price is around $4000.

Advantages

- Reduce material costs

- No secondary damage

- Improve performance of belt buckles, straps, etc.

- Easier to operate

Disadvantages

- Increase chances for personal injury when working near moving parts or blades

- Non-standardized equipment

- Cannot be used as a solid rivet machine or vice versa. In addition, they do not share the same dies.

- Low accuracy in rivet installation for jogging the fabric or leather body limited surface-so that eyelet is not visible from outside.

16. Steel Riveting Machine

A steel riveting machine is a type of rivet tool that has interchangeable heads for different types of rivets, allowing fast installation of both solid and hollow rivets with the same machine. The machine applies pressure onto the rivet through two movable plates in order to form the rivet’s head. All steel riveting machines can be mounted on a workbench for ease of use.

The steel riveting machine works by using a vertical ram to drive the rivet between two flat dies. It is capable of applying force up to 35 tons when properly adjusted and lubricated. The normal stroke length for this machine is 4″. The approximate price of this machine ranges from $150- $7000.

Advantages

- All heads are interchangeable to perform different riveting tasks

- Easier to use (install) than other types of rivet tools

- Rivets of consistent force applied by machine

Disadvantages

- All heads are interchangeable, which can result in multiple misaligned or mismatched rivets

- Decreased material strength due to inconsistent forces applied by machine

- Newer models are not compatible with most types of rivets

17. Grommet Rivet Press

There are a variety of riveting machines on the market, but one of the most versatile is the grommet rivet press. This machine is an industrial type of riveting machine used to assemble aluminum wheel rims, plastic window profiles, fuel tanks, and other types of large containers that typically require the use of blind rivets.

This machine can be used to install grommets in all kinds of materials, from cloth and vinyl to leather and plastic. It’s also perfect for installing eyelets in materials like leather or canvas. The grommet rivet press is a must-have tool for any craftsman or seamstress.

The process of using this machine is simple, with an automatic action that pulls the rivet through the material to be joined while also setting it in place. All this is done with one simple squeeze of a handle. This machine cost around $1,495.

Advantages

- High speed of installation

- No secondary damage

- Lower the rate of damaged rivets

Disadvantages

- The machine can be heavy, may require two people to move it around

- Expensive investment cost

- High maintenance costs due to frequent repair and preventative maintenance work

- Requires more personnel to operate it

18. Metal Riveting Machine

A metal riveting machine is a type of rivet tool that applies the correct amount of pressure to form a perfect head on any solid or tubular blind, pop, or flush rivet. All types of steel and aluminum rivets can be installed quickly and easily with this type of industrial-grade tool.

The metal riveting machine is a device that is used to join two pieces of metal together by driving a rivet through the pieces. The rivet is a cylindrical piece of metal that is inserted into the hole that is drilled in the two pieces of metal. The rivet is then hammered until it expands and locks the two pieces of metal together.

The metal riveting machine application is similar to the operation of a staple gun. All that is required is for the operator to squeeze the handle, puncture the pieces of metal, and then release it.

The approximate cost for a metal riveting machine ranges from $380 to $510.

Advantages

- Great for high-volume riveting

- No need to dismount the rivet shank

- Greater access of machine-operated tool

Disadvantages

- Expensive investment

- Need a great number of skilled operators

- Rivets of inconsistent sizes

19. Tubular Rivet Machine

A tubular rivet machine is used for forming tubular rivets by using hydraulic pressure. It can form all types of tubular rivets like a plain annealed rivet, plainly drawn rivets, all aluminum rivets, etc.

The cost of a tubular riveter machine depends on the size and type of machine that is required. Generally, the cost ranges from USD 2000 to USD 20000.

Advantages

- Easy to operate

- Few moving parts

- High efficiency

- No lubrication needed

Disadvantages

- High working pressure

- High initial cost

20. Bimetal Rivet Machine

A bimetal rivet machine is used to produce all types of rivets that are specially used for all aluminum, all steel and all stainless steel structures. The different types of all aluminum all steel all stainless steel rivets include plain annealed, drawn wire etc.

The basic feature of a bimetal machine rivet is that all types of all aluminum, all steel, all stainless steel rivets can be produced by the same machine.

The cost of a bimetal rivet machine ranges from USD 8500 to USD 15000.

Advantages

- High quality products

- Easy to use

- Versatile

Disadvantages

- Needs regular lubrication

- Requires extensive maintenance

- Can be costly to repair

- Takes up a lot of space

21. Bimetal Rivet Making Machine

The bimetal rivet making machine works on the principle of hydraulic pressure to produce all types of alluminum german rivets with high speed and accuracy. It can produce rivets ranging in length from 1/2″ to 6″.

Bimetal rivet making machine is the latest and modern technology of all aluminum rivet making machines. It can make all types of alluminum rivets but its thickness varies from 0.5 mm to 2 mm.

It consists of all required accessories like hydraulic system, screwing unit etc. In all range it can be customized according to the alluminum rivet type.

The alluminum bimetal rivet making machine costs varies depending on the size and features of the machine. Generally, it ranges from USD 18,000 to USD 25,000.

Advantages

- High quality end products

- Durable

- Reliable

Disadvantages

- Takes up a lot of space

- Experienced personnel needed

- Requires time and effort to maintain

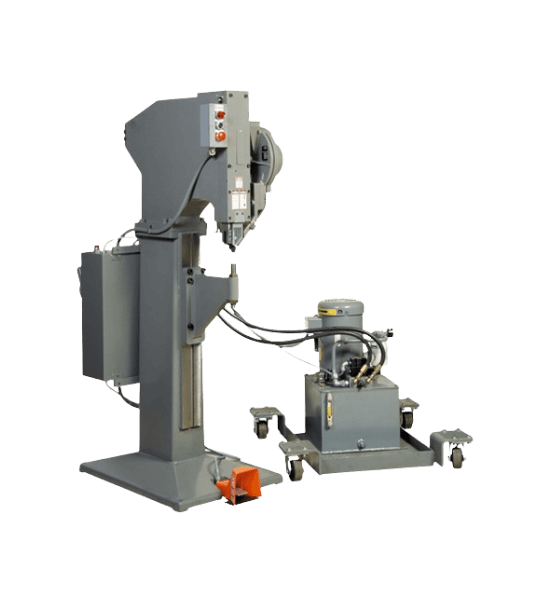

22. CNC Riveting Machine

A CNC riveting machine is a computer-controlled machine that is used to join two pieces of metal together by using a rivet. It is a relatively new technology that has many benefits over traditional riveting methods.

The CNC riveting machine is made up of a welded steel solid frame and a protective shell made up of aluminum pieces with polycarbonate glass. A fast movement speed is possible because of the dynamic drive of the coordinate axes via recirculating ball screws, servo motors, and the motion control unit. The riveting units are mounted on solid C-shaped frames.

Advantages

- Hydraulic-driven

- Save labor cost

- Increase production capacity

- Easy to use machine

- Improves quality of end product

- Reduced maintenance costs due to higher automation level

- High flexibility

Disadvantages

- High initial investment

- Replaceable wear parts are expensive

- Requires high maintenance

- Require a long training process for operators to use the machine

The price of a CNC riveting machine varies depending on the size, type and features of the machine. Generally, it costs from USD 30,000 up to USD 100,000. They are more expensive than other types of riveting machines, but the benefits of using a CNC riveting machine often outweigh the cost.

23. Chassis Rivet Machine

The Chassis Rivet Machine is a great all-around machine that is perfect for both heavy and light-duty construction. It can install all types of rivets, including tubular rivets.

These types of riveting machine are used to put all-threads on an aluminum chassis. The all-threads are then melted with a torch. This solution simulates welding, but does not damage the all-thread or chassis because all-thread has very low tensile strength and therefore unable to hold all-threads on the chassis.

Advantages

- High production rate

- Easy to use

- Large varieties of all-threads and rivets available

Disadvantages

- Lower strength than welded solution

- Can fail if all threads not installed straight

- Require all threads to be melted with a torch

- Higher costs than most riveting methods

The price of a chassis rivet machine is USD 14000 to USD 18000. The machine can be used for light and heavy duty projects, but is not as heavy duty as a hydraulic all-threader.

24. Rivet Header Machine

Header machines are investment casting machine that is capable of pulling all kinds of rivet. Rivets can be alloys made of iron, stainless steel rivet or copper rivet. The main function pull all kinds of rivet.

The main function of these riveting machines is to pull all types of metal fasteners fitted with a head on them so that they will stick through the hole in the workpiece created by another piece of equipment.

The more popular ones are all-inclusive sheet metal footings for heavy duty construction. They typically have an open top head to fit different shapes and sizes strait or tubular rivets made from iron or stainless steel material.

Advantages

- Affordable and readily available

- Easy to use

- High production rate

- Reduced labor costs

Disadvantages

- Low quality of the product

- No control of rivet size

- Can only fit some specifications for parts

- Lack of head space, causing bent rivets or part misalignment

- Shorter life span compared to cold header machine

- High maintenance cost due to frequent breakdowns

The cost of a rivet header machine can vary depending on the brand, the features, and the size. Generally, these machines can range from $1,000 to $10,000.

25. Rivet Machine for Fabric

This is the most basic type of rivet machine, and it is used for joining two pieces of fabric or metal together. It can be used for a variety of applications, including fabricating clothes, manufacturing parts, and repairing equipment.

Some machines are designed for light-duty use, while others are more heavy-duty and can be used for tougher fabrics. It is important to choose the right rivet machine for your needs, depending on the type of fabric you are working with.

Advantages

- It is easy to use.

- It is a versatile tool that can be used for a variety of applications.

- It is affordable.

- It is durable and can withstand heavy use.

- It is environmentally friendly.

Disadvantages

- It can be difficult to use if you are not familiar with the machine.

- It can be challenging to find the right rivet machine for your needs, depending on the type of fabric you are working with.

Therefore it is important to choose the right rivet machine for your needs, depending on the type of fabric you are working with.

26. Rivet Machine for Jeans

A rivet machine for jeans is specifically designed to join denim fabric together. It is usually equipped with a set of dies that are specifically designed to punch holes in denim. It is important to use the right rivet machine for your fabric, or else you could end up ruining it.

Rivets are used to hold two pieces of fabric together or to reinforce a weak spot in the fabric. Jeans are commonly held together with rivets at the seams and the pockets. The rivets help to reinforce the fabric and keep it from tearing. Rivets can also be decorative, and they often add character to a piece of clothing.

Advantages

- They are very sturdy and can hold up a lot of weight.

- They are very durable and can last for a long time.

- They are easy to use and can be operated by anyone.

- They are relatively cheap to manufacture and purchase.

Disadvantages

- They cannot be used with all fabrics, such as silk and other delicate materials.

- They can damage or break the rivet gun and the rivets.

- They can be difficult to remove and repair if they are not installed properly.

Overall, rivets and rivet machines for jeans can be very useful in a variety of situations. As long as you choose the right rivets and rivet machine for your fabric, they should not cause any problems.

27. Punch Rivet Machine

Punch rivet machine is a type of rivet machine that is used for punching a hole in the material and then riveting the two pieces of material together. It is a very common type of rivet machine and is used for a variety of applications. The punch rivet machine is capable of making a range of holes from 3mm to 20mm in diameter.

For the punch rivet machine to work, it uses ahydraulicand pneumatic system. All this does is drive the pistons which in turn pushes the punch through the material. All the machines made today are compatible with all types of rivets. The punch rivet machine has one purpose and that’s to punch holes in solid pieces of material to fasten them together.

Advantages

- The ability to punch a wide range of hole sizes.

- The machine can work with all types of rivets.

- The punch rivet machine is inexpensive.

- It can be used for a variety of applications.

Disadvantages

- The machine is only able to work with solid pieces of material.

- It only can punch holes to fasten material together.

- It has limited accuracy in comparison to other rivet machines available today.

Therefore, using punch rivet machines has its advantages and disadvantages. This is why it’s important to know exactly what you need the machine to do before investing in one.

28. Small Riveting Machine

A small riveting machine is a great option for those who need a compact and portable riveting tool. This type of machine is perfect for smaller projects, and it can be easily transported from one work site to another.

If you’re looking for a small but powerful riveting machine, then the pneumatic riveting machine is a great option. This type of machine usescompressed airto drive the rivet into place. This type of machine is excellent for repetitive projects, and it can drive sturdy metal rivets into surfaces that are up to 10 millimeters thick.

Advantages

- Compact design is perfect for working in tight spaces.

- Ideal option when you need a riveting machine on the go.

- All pneumatic rivet machines are designed for repetitive use.

- All pneumatic rivet machines are designed for metal materials that are up to 10 millimeters thick.

- Good for a home workshop or personal use.

Disadvantages

- Difficulty in riveting large parts.

- Limited range of rivets that can be used.

- Cannot be used on curved surfaces.

Small Riveting Machine has its advantages but also has some disadvantages. So, each machine is good for a specific job and therefore the user must choose the right machine based on his requirements.

29. Sheet Metal Riveting Machine

A sheet metal riveting machine is specifically designed to join two pieces of sheet metal together. This type of rivet machine may be equipped with dies that are especially for this purpose.

All types of sheet metal riveting machines are suitable for different applications, some are used in heavy industry, while some are meant only for the hobbyist. All sheet metal riveting machines are built to handle the stress of heavy-duty applications, so you can rest assured they will not break in mid-use.

Advantages

- They are stress-resistant and can handle heavy-duty use

- They are built for a variety of applications

- Some of these machines offer interchangeable dies so you can use them in a variety of applications

- They can also be equipped with a foot pedal so you can control the use of the machine

- The operation is easy and it does not require a knowledgeable person to run the machine

- The sheet metal riveting machines are popular among hobbyists because they can handle a variety of applications

Disadvantages

- Sheet Metal Riveting Machine can be expensive to purchase and maintain.

- Sheet Metal Riveting Machine can be time-consuming to use.

- Sheet Metal Riveting Machine may not be a good choice for a novice.

Overall, Sheet Metal Riveting Machine can be a good purchase for someone who is looking for a variety of applications. They are easy to use, versatile, and suited for different applications.

30. Rivet Manufacturing Machine

A rivet manufacturing machine is specialized equipment used for the mass production of rivets. It typically consists of a moving head that holds the rivet, a die where the rivet is formed, and a means of feeding the rivet into the die.

There are all kinds of rivet machines, from small-scale hand-operated units to large-scale automatic machines that can produce thousands of rivets per minute. The main purpose of a rivet manufacturing machine is to speed up the process of manufacturing rivets.

By using a machine instead of doing it by hand, it can significantly reduce the time it takes to make rivets. In addition, a machine can also produce more consistent results than someone working by hand. This is because human error is removed from the equation, thus resulting in a more reliable product.

Generally, rivet machines are used in metalworking applications. They can be found in a wide range of industries including shipbuilding, construction, the automotive industry, and more. All kinds of rivet machines can be used anywhere that requires the use of rivets.

Advantages

- Increased production speed

- Consistent results

- Reduced labor costs

- Wide range of applications

Disadvantages

- There is a greater initial investment.

- Requires more space.

- Can be dangerous if not properly used.

- Can be complicated to understand how it works.

Therefore, Rivet Manufacturing Machine is very helpful in the business/industry. All kinds of rivet machines can be used anywhere that requires the use of rivets. For more information on rivet manufacturing machines, you can visit our website at Riveth.com.

31. Advantages and Disadvantages of Riveting

| Advantages | Disadvantages |

|---|---|

| Relatively inexpensive method. The production of the rivet is cheap. | Riveting take more labor time than welding. Additional operations like lay out and drilling holes are necessary. The labor cost of rivet joints is high. |

| Rivet can be used in joining of ferrous as well as a nonferrous metal like aluminium and copper alloys. | Stress concentration at the rivet holes of metal plates. |

| Rivet can be used in joining of ferrous as well as a nonferrous metal like aluminium and copper alloys. | The holes may weaken the working cross section of the plate. Then the additional thickness is required to compensate for this problem. This additional thickness and overlapping of plates for riveting increases metal consumption. |

| One of the main advantages of the rivet is that it can use to join dissimilar materials. (eg: joining aluminum plate and copper plate). | It has more weight than welded joint due to strap-plate and rivets. |

| Ability to make joint regardless of the location. (Vertical, overhead, etc.) | The riveted joints are bulkier than welding and brazing. The projection of rivet also affects aesthetic appearance. |

| No fumes and gases produced as in the welding, the production is environmentally as well as user-friendly. | They typically do not make a tight or leak-proof joint unless using hot rivet or sealant along the rivet. |

| Riveted joints are reliable than other methods in applications where the joint subjected to excessive vibration and impact forces. | The riveting process is noisier than welding due to hammer blowing. |

32. Conclusion

So there you have it – everything you need to know about rivet machines.

If you’re still unsure of which machine is best for your needs, or if you have any other questions, don’t hesitate to contact us at Riveth. We’ll be more than happy to help!

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.