PRODUCT FEATURES

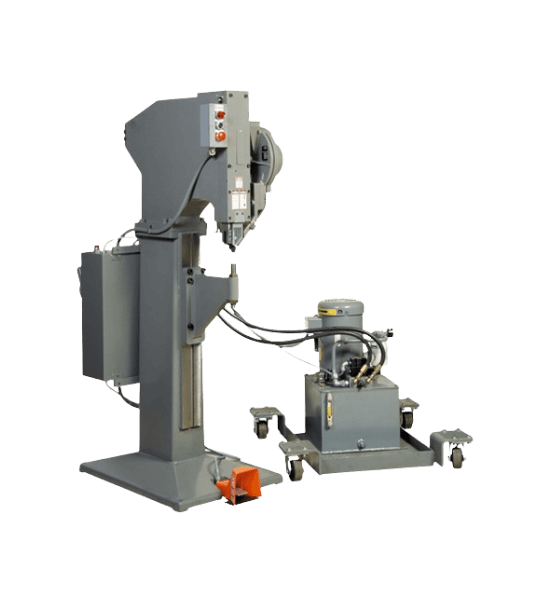

Orbital Riveting Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Orbital Riveting Machine: The Ultimate Guide

Are you in the market for an orbital riveting machine? If so, you’re in luck. In this Ultimate Guide, we’ll show you what to look for when buying an orbital riveting machine and share our top picks for the best models on the market.

When it comes to riveting, there are a few different types of machines that you can use. With the long list of those different machines, we know for sure that it might confuse you with which one to choose. In this guide, we’ll discuss what orbital riveting machines are, how they work, and why you should consider using one in your business.

By the end of this article, you’ll know everything you need to know about orbital riveting machines and be able to decide if one is right for you. So let’s get started!

Table of contents

1

What Is an Orbital Riveting Machine

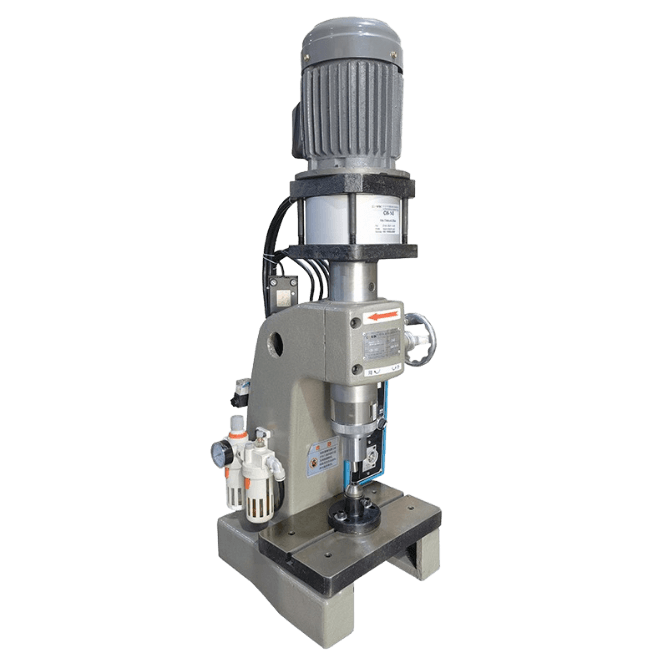

An orbital riveting machine is a type of riveting machine that uses orbital motion to drive the rivet. This type of machine is often used in high-production settings, automation, and processes as it can rivet quickly and efficiently.

There are several different types of orbital riveting machines, each with its advantages and disadvantages. Some machines are designed for use with specific types of rivets, while others are more versatile.

It is important to choose the right orbital riveting machine for the job, as using the wrong machine can lead to poor results that may deliver to damages and accidents. Orbital riveting machines are a valuable tool for any shop that does a lot of riveting.

They can save time and increase productivity by allowing workers to quickly and efficiently install rivets and do process monitoring. When choosing an orbital riveting machine, it is important to consider the types of rivets that will be used, as well as the applications for which the machine will be used.

2

Uses of an Orbital Riveting Machine

An orbital riveting machine is a type of riveting machine that uses a rotating head to join two pieces of metal together. The effectiveness of this type of machine is often observed and used in the services of aerospace and automotive industries.

There are several different applications for this type of machine, including the following:

- Joining two pieces of metal together.

- Repairing metal parts.

- Assembling metal parts.

- Bonding metal parts.

- Fastening metal parts.

An orbital riveting machine is a versatile tool that can be used for a variety of tasks in the metalworking industry. If you are looking for a reliable and durable machine that can join metal parts together, then an orbital riveting machine may be the right option for you.

3

How Does an Orbital Riveting Machine Work

How does an orbital riveting machine work? The rivet gun on the orbital riveting machine contains a rivet and a mandrel. When the trigger is pulled, the mandrel is forced into the rivet, which expands the rivet and secures it in place.

The orbital motion of the machine then ensures that the rivet is properly seated in the joint. Here’s a look at how orbital riveting machines work:

The orbital rivet gun is placed over the joint to be formed. The mandrel is inserted into the end of the rivet and then pulled until it has reached its maximum length on the opposite side of the joint.

The trigger is pulled. This moves the mandrel into the rivet, which expands it and secures it in place. The orbital motion of the orbital riveting machine ensures that the mandrel is properly seated in the joint.

Once this has been accomplished, a pin is inserted through a hole in one end of the rivet to hold it securely in place. An orbital riveting machine is a type of riveting machine that uses orbital motion to join two or more pieces of metal together.

This type of machine is often used in the automotive and aircraft industries, as it can produce a downward pressure and high-quality rivet joint without causing damage to the surrounding metal.

4

Cost of an Orbital Riveting Machine

Given the manufacturing details and materials, this orbital riveting machine costs anywhere from $1,000 to $10,000. The price depends on the size and power of the machine. orbital riveting machines are a great option for businesses that do a lot of riveting because they can save time and money.

Orbital riveting machines vary in price but can be costly. They are often used in high-volume production settings, so the price of the machine is relative to how much it will be used.

Orbital riveting machines can range anywhere from a few thousand dollars to tens of thousands of dollars. The price of an orbital riveting machine is often reflective of its quality and features.

If you are looking for a high-quality machine that is capable of doing a lot, then you will likely have to pay more for it. However, there are also lower-cost options available if you are willing to sacrifice some features or quality.

Orbital riveting machines are high-cost pieces of equipment. The cost of an orbital riveting machine varies depending on the size and type of machine. Generally, the larger the machine, the more expensive it will be.

5

Benefits of Using an Orbital Riveting Machine

There are many benefits of using an orbital riveting machine. Some of these benefits include:

Increased Productivity

Orbital riveting machines are fast and efficient, which means that you can get the job done quickly with just one press and effort.

Improved Quality

With orbital riveting machines, you can achieve a high level of quality in your work. This is because the machines are very precise and consistent. It is very easy to control and no installation needed.

Increased Accuracy

The orbital riveting machine is extremely accurate, which means that your work will be precise and there will be fewer mistakes.

Reduced Costs

Orbital riveting machines are more affordable than other types of riveting machines, which means that you can save money in the long run.

6

Things To Consider Before Purchasing an Orbital Riveting Machine

When it comes time to purchase an orbital riveting machine, there are a few key things to keep in mind aside from the material, the shape, and tools. Here are things to consider before you make your purchase:

#1. Size of the Machine

Make sure to choose a machine that is the right size for your needs. If it’s too small, it won’t be able to handle the jobs you need it to, and if it’s too big, it will take up too much space and be more difficult to move around.

#2. Power of the Machine

The power of the machine will determine how well it can handle different jobs. Make sure to select a model that has enough power for the tasks you plan to use it for.

#3. Cost of the Machine

You don’t want to spend too much on an orbital riveter. Compare prices on different models before making a decision.

#4. Availability of Replacement Parts

If something goes wrong with the machine during the manufacturing process, you want to make sure that the replacement parts are readily available.

#5. Ease of Use

Make sure the machine is automatically set and easy to operate so that you can use it with ease.

The orbital riveting process and orbital forming are essential for any business that wants to be successful in today’s competitive market. It provides durability and strength without compromising quality or aesthetics by creating a permanent bond between two pieces of metal.

Orbital riveting and its riveting cycle is a simple process, but there are many orbital riveting machines available. Make sure to choose one that meets your specific needs and budget!

7

6 Tips on How To Use an Orbital Riveting Machine Safely and Effectively

An orbital riveting machine is a powerful tool that can be used to join or fasten two pieces of metal together. It can be a dangerous tool if not used correctly during its cycle time, so it is important to follow these safety tips when using an orbital riveting machine in your construction area or any site:

| No. | Tips |

|---|---|

| 1 | Always Wear Safety Gear |

| 2 | Make Sure Your Surrounding Is Clear |

| 3 | Don’t Over-tighten the Rivets |

| 4 | Keep Your Hands Away From the Moving Parts |

| 5 | Don’t Leave the Machine Unattended |

| 6 | Unplug the Machine After Use |

#1 Always Wear Safety Gear

Always wear safety goggles when using an orbital riveting machine. This will protect your eyes from any debris or sparks that may come flying off the metal.

#2 Make Sure Your Surrounding Is Clear

Making sure the area around you is clear before beginning to rivet is extremely important. You don’t want any debris getting in the way and causing you to lose focus while riveting. Make sure to clear the area yourself, and also to ask anyone else nearby to move out of the way.

#3 Don’t Over-tighten the Rivets

Do not over-tighten the rivets – they should be snug, but not tight. Use downward force if possible. Overtightening the rivets can cause them to break, which can be very dangerous. You might find it a challenge at first but surely, you’ll get used to how to use this riveting unit.

#4 Keep Your Hands Away From the Moving Parts

It is important to always keep your hands and fingers clear of the moving parts of the orbital riveting machine. If they get caught in the moving parts, it can cause serious injuries.

#5 Don’t Leave the Machine Unattended

Leaving the orbital riveting machine running unattended can be very dangerous. If something goes wrong while the machine is running, you may not be able to get to it in time to stop it. Make sure to always stay close to the machine while it is running, and be prepared to stop it if necessary.

#6 Unplug the Machine After Use

Shut off the machine and unplug it when you are finished using it. This will help ensure that the machine is safe to use the next time you need it.

By following these safety tips, you can use an orbital riveting machine safely and effectively.

Here’s a quick video on how to use Orbital Riveting Machine:

8

Different Types of Orbital Riveting Machines

There are two different types of orbital riveting machines. The most common are the pneumatic orbital riveting machines and the electric orbital riveting machines.

Pneumatic Orbital Riveting Machine

Pneumatic orbital riveting machines use compressed air to power the riveting tool. The pneumatic orbital riveting machine uses compressed air to power the riveting head. This type of machine is portable and easy to use, making it a popular choice for smaller projects.

Electric Orbital Riveting Machine

Electric orbital riveting machines use electricity to power the tool. The electric orbital riveting machine uses electricity to power the riveting head.

This type of machine is more powerful than the pneumatic orbital riveting machine and is better suited for larger projects.

There are also orbital riveting machines that use a combination of compressed air and electricity to power the riveting head. These machines offer the best of both worlds, with portability and power in one machine.

Which orbital riveting machine is right for your project? That depends on the size and scope of your project, as well as your budget. If you have any questions about orbital riveting machines, please contact us at Riveth today they’d be happy to help!

9

4 Tips for Maintaining Your Orbital Riveting Machine

An orbital riveting machine is a valuable tool for any business, but it’s important to keep it in good condition to ensure that it continues to be effective. Here are some tips for maintaining your orbital riveting machine:

#1 Keep the Machine Clean

The riveting head and surrounding area should be cleaned regularly with a dry cloth. This will help to keep the machine in good condition and ensure that it continues to function properly.

#2 Lubricate the Moving Parts

A light film of oil should be applied to the piston rod, hinge pin, and other moving parts every few months. This will help the machine run smoothly and prevent it from becoming clogged or jammed.

If you’re having trouble getting the riveting head to move up and down, you may need to apply more oil. Be careful not to get any oil on the riveting head itself, as this could cause problems with the riveting process.

#3 Keep the Screws and Bolts Tight

Check all screws and bolts regularly and tighten them as necessary. This will help keep the machine in good condition and prevent it from breaking down.

#4 Inspect the Riveting Head Occasionally

If you see any damage or wear, replace the riveting head immediately. This will help to keep your orbital riveting machine in good condition and functioning properly.

By following these tips, you can help keep your orbital riveting machine in good condition and ensure that it continues to be a valuable asset for your business.

10

Conclusion

Orbital riveting machines are a great choice for businesses that need to quickly and easily join two pieces of metal together. If you’re in the market for an orbital riveting machine, we can help you find the perfect model for your needs and get you set up with all the supplies you’ll need to start riveting like a pro.

We’ll show you what to look for when buying an orbital riveting machine and share our top picks for the best models on the market. Contact us today if you have any questions about choosing or using an orbital riveting machine in your business.

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.