PRODUCT FEATURES

Rivet Machine Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Rivet Machine: The Ultimate Guide

There is no question that a rivet machine is an essential tool for the construction industry. But with so many options on the market, it can be tough to know which one is right for you.

In this guide, we will walk you through everything you need to know about rivet machines. We will discuss the different types of rivet machines and provide some tips on how to use a rivet machine safely and effectively.

Let’s get started!

Table of contents

1. What Is a Rivet Machine

A rivet machine is a tool that uses high pressure to join two pieces of metal together. Rivets are inserted into the rivet gun, and the rivet machine creates enough pressure to push the rivet through the two pieces of metal.

The advantage of using a rivet machine is that it can create a permanent bond between two pieces of metal. This makes rivet machines a great option for projects that require strong joints and fasteners, such as sheet metal work or automotive repair.

Rivets can be made from aluminum, steel, stainless steel, copper or brass. The rivet machine pushes the rivet through the two pieces of metal to create a permanent bond. It is equipped with anvils on each side to help form the rivet into a dome shape.

2. Uses of a Rivet Machine

There are many different applications for rivet machines, but the most common uses are:

- Joining metal sheets together

- Fastening automotive parts together

- Repairing boat hulls and decks

- Assembling furniture or other household items

- Tooling and manufacturing

Rivet press machine can also be used to repair holes in metal, such as riveting a patch onto an airplane wing or riveting a hole that was drilled into the hull of a boat.

Rivets can also be used for more decorative purposes, like riveting coins together to make jewelry or riveting tiny pieces of colored glass together to create mosaics.

3. Cost of a Rivet Machine

The rivet machine price will vary depending on the type and size of the machine that you choose. However, most rivet machines cost between USD 200 and USD 800.

If you are looking for a rivet machine for sale but on a budget, you may want to consider purchasing a riveter machine from China. The cost of a rivet machine supply from China can be as low as USD 50.

It is also important to note that rivet machines require regular maintenance to keep them running effectively. The cost of maintaining a rivet making machine can be anywhere from USD 50 to USD 100 per year.

4. Purchasing a Rivet Machine From China

If you are looking for a cheaper option, you can also purchase a rivet machine from China. The downside of purchasing a rivet machine is that the quality may not be as good as machines made in the United States or Europe.

However, if you are looking for a basic rivet machine at a lower price, then a Chinese-made rivet machine may be a good option for you.

5. 6 Tips on How To Choose the Right Rivet Machine for Your Needs

Here are some tips on how to choose the right rivet machine for your needs.

#1 Choose the Right Size

The rivet size should be similar to the thickness of the metal you are working with. If your rivets are too small, then they will not hold as well or last as long; if your rivets are too large, then it may take longer for them to rivet through the metal.

#2 Choose the Right Type of Rivet Machine

There are many different types of rivet machines, so it is important to choose the right machine for your project. If you are working with a lot of heavy-duty metalwork, then you will need a heavier-duty automatic rivet machine to increase production capacity.

If you are working on smaller projects or decorative pieces, then you may be able to get away with a smaller, lighter-duty rivet machine.

#3 Consider the Cost of Maintenance

Aside from rivet machine cost, it is important to consider the cost of maintaining your rivet machine. If you are not comfortable doing the maintenance yourself, then you will need to factor in the cost of having a professional do it for you.

#4 Choose the Right Rivet Material

The rivet material should be compatible with the metal you are working with. For example, brass rivets can be used on aluminum sheets, but steel rivets should not be used on aluminum sheets.

#5 Consider Your Budget

It is important to consider your budget when choosing a rivet machine. Rivet making machine price can range from USD 50 to USD 800, so it is important to choose the right machine for your needs and your budget.

#6 Buy From a Reputable Supplier

It is important to buy from a reputable rivet machine supplier such as Riveth. If you are looking for rivet machines for sale, then you should consider buying one from China.

If you are not comfortable with purchasing your rivet machine online, then many different companies sell riveting machines in person as well.

If possible, try out different types of rivet machines before making a purchase. This will help you to determine which rivet machine is best for your needs.

6. Different Types of Rivet Machines

When choosing a rivet machine, it is important to know all kinds of rivet machine and consider the type of work that you will be using it for. Here are some of the most common types of rivet machines:

Manual Rivet

These rivet machines are best used for smaller projects. They do not require electricity or air pressure, which means that they can be used anywhere and anytime. The rivets need to be manually pulled through the rivet gun by hand to create a permanent bond between two pieces of metal.

Pneumatic Rivet Guns

These rivet machines are best used for larger projects. They require electricity or air pressure to rivet the rivets through two pieces of metal.

Automatic Rivet Machines

These rivet machines are best used for larger projects. They rivet rivets through two pieces of metal automatically, but they do require electricity or air pressure to function properly.

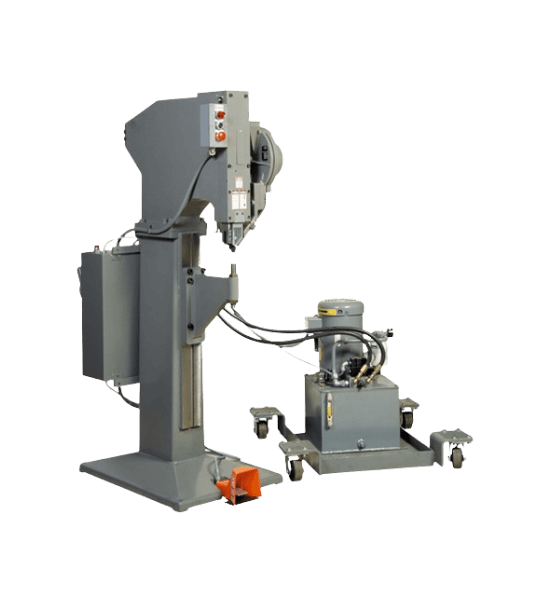

Hydraulic Riveters

These rivets machines are best used for heavy-duty projects. They require a lot of power to rivet the rivets through two pieces of metal.

These 4 machines are just some of the most common types. More types of rivet machine are as follows:

- Radial Riveting Machine

- Button Rivet Machine

- Hot Riveting Machine

- Aluminium Rivet Machine

- Hydraulic Rivet Machine

- Industrial Rivet Machine

- Rivet Machine For Leather

- Spin Riveting Machine

- Foot Press Rivet Machine

If you are not sure which type of rivet machine is best for your needs, then you can consult with a rivet specialist or manufacturer to help you choose the right rivet machine for your project.

7. 6 Tips on How To Use a Rivet Machine Safely and Effectively

Here are some tips on how to use a rivet machine safely and effectively:

#1 Wear Safety Gear

It is important to wear safety gear when riveting within the location. The riveting equipment can be dangerous if not used correctly and safely; it can cause serious injury or even death if used improperly.

#2 Make Sure Place is Safe

Make sure that the area you are working in is also safe. Make sure there are no flammable materials or liquids near the rivet machine, and be cautious when using the rivet gun around other people.

#3 Always Read the Manufacturer’s Manual

This will give you instructions on how to rivet properly with the rivet gun and will also have safety guidelines that should be followed. It is important to follow these safety guidelines carefully to prevent accidents or injury while riveting.

#4 Rivet Machine is Properly Calibrated

Make sure that the rivet machine is properly calibrated before riveting. If it is not, then you may have problems riveting correctly and could cause damage to yourself or others if used improperly.

When riveting, hold the rivet gun securely against the work piece with one hand and use the other hand to pull the trigger. Be careful not to put your fingers in front of or behind the rivet when firing it.

#5 Keep Away From Children

Keep the rivet machine and its accessories out of reach of children. Children should never be allowed to use or play with a rivet gun, as they can easily cause injury if not used correctly.

#6 Use the Right Rivets

Be sure to use rivets that are appropriate for the machine you are using and the project you are working on. Using the wrong rivet could cause damage to both the rivet gun and the work piece, and may also result in injury.

When riveting, always be aware of your surroundings and take precautions to ensure your safety and the safety of others. A rivet machine is a great tool to have in your arsenal, but it is important to use it safely and effectively. By following these tips, you can ensure that your rivet machine will work properly and safely every time.

8. 5 Tips for Maintaining Your Rivet Machine Over Time

Here are some rivet machine maintenance tips that you can use to keep your rivet gun working properly and safely for years:

| No. | Tips |

|---|---|

| 1 | Clean Your Rivet Machine Regularly |

| 2 | Lubricate Your Rivet Machine Regularly |

| 3 | Inspect For Loose or Worn Parts |

| 4 | Check for Any Cracks of Breaks |

| 5 | Read and Follow the Instruction Manual |

#1 Clean Your Rivet Machine Regularly

This will help to keep it in good working condition and prevent dirt and debris from gumming up the works.

#2 Lubricate Your Rivet Machine Regularly

This will help to keep the rivets moving smoothly and prevent them from rusting or jamming up. Use oil to keep all of the moving rivet machine parts lubricated. This will help to ensure that your rivet machine runs smoothly and doesn’t get stuck.

#3 Inspect For Loose or Worn Parts

A rivet machine is a precision tool, and the rivets can come loose or wear out over time. If you notice that your rivet gun is not working properly, then it may be time to replace some of its parts.

#4 Check for Any Cracks of Breaks

If you notice any rivets that are cracked or broken, then they need to be replaced. These can cause serious injuries if left unchecked, so it is best to repair any issues as soon as possible.

#5 Read and Follow the Instruction Manual

It is always a good idea to read the manufacturer’s instructions for your machine rivet before using it. This will help to ensure that you are using it safely and effectively.

By following these tips, you can keep your rivet machine in good condition and prevent any accidents or injuries from occurring.

9. Troubleshooting Common Problems With Rivet Machines

Sometimes rivet machines can malfunction. This can happen for several reasons, but some common problems often occur with rivet machines.

Here are a few ways to help you troubleshoot and fix common rivet machine problems:

Ensure Machine is Properly Plugged In

If the rivet gun is not firing, check to make sure it is properly plugged in and that there is power going to it. If it is plugged in and there is power, try replacing the fuse or resetting the breaker.

Adjust Air Pressure

If the rivet gun is firing but the rivets are not seating properly, you may need to adjust the air pressure. You can do this by turning the adjustment knob on the gun.

Adjust the Rivet Force Setting

If rivets are coming out deformed or with a large hole in them, you may need to adjust the rivet force setting. This can be done by turning the adjustment knob on your rivet gun.

Adjust the Speed

If rivets are coming out of the materials too quickly, you may need to slow down the speed at which they are ejected from the rivet machine. This can be done by adjusting the speed control knob on the rivet gun.

Check the Nozzle

If rivets are coming out of the machine crooked, it may be because the nozzle is not aligned properly. You can check and adjust the alignment of the nozzle by loosening the thumbscrews on either side.

Clean the Nozzle

If rivets are coming out of the machine with a black residue on them, it may be because the nozzle is dirty. You can clean the nozzle by using a wire brush or air compressor.

These are some common problems that can occur with rivet machines. If you are experiencing any of these issues, try troubleshooting them with these tips.

You might want to check out this video on How to use Rivet Machine.

10. Conclusion

Rivet machines are a great way to join materials together quickly and efficiently. They can be used for a variety of applications, from home repairs to industrial manufacturing.

We want to make sure you are getting the best rivet machine for your needs, which is why we have compiled this list of tips to help you troubleshoot any malfunctions.

If you have any questions about rivet machines, do not hesitate to contact us at Riveth. We would be more than happy to assist you.

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.