PRODUCT FEATURES

Hot Riveting Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

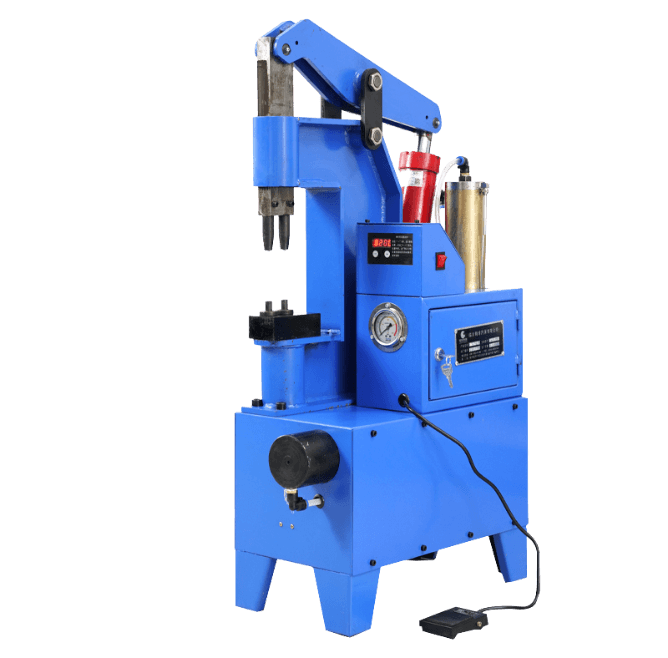

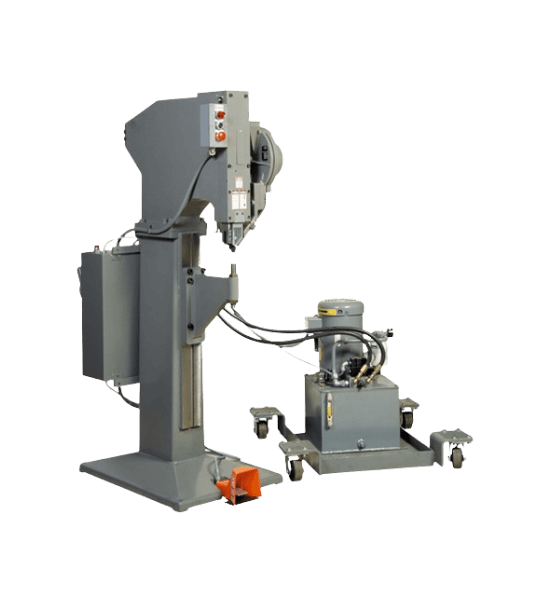

Hot Riveting Machine

A hot riveting machine is a great way to join two pieces of metal together. It is very strong and can hold up under a lot of pressure, making it perfect for use in a variety of industries, including automotive, construction, and manufacturing.

Available in many different sizes, depending on the size (material) of the pieces to be joined. Hot riveting machines can easily join steel, aluminum, and stainless steel. Hot riveting is also beneficial when joining dissimilar metals.

A hot riveting machine works by heating the rivet, which in turn makes it soft and able to flow into place. Hot riveting allows for much faster production than cold welding or spot welding in certain cases, making it more efficient in many industries.

Hot rivets can be used at a lower temperature to maintain optimal tooling temperature than spot welding, but are more difficult to make.

Table of contents

1

Hot Riveting Machine Definition and What Does It Do

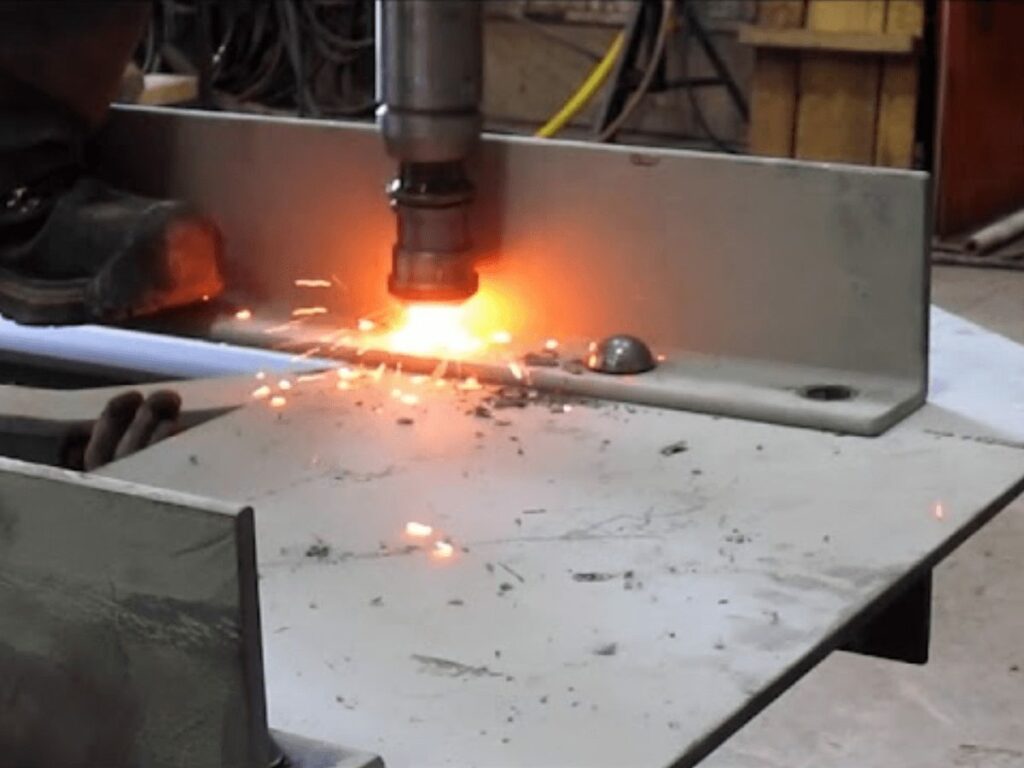

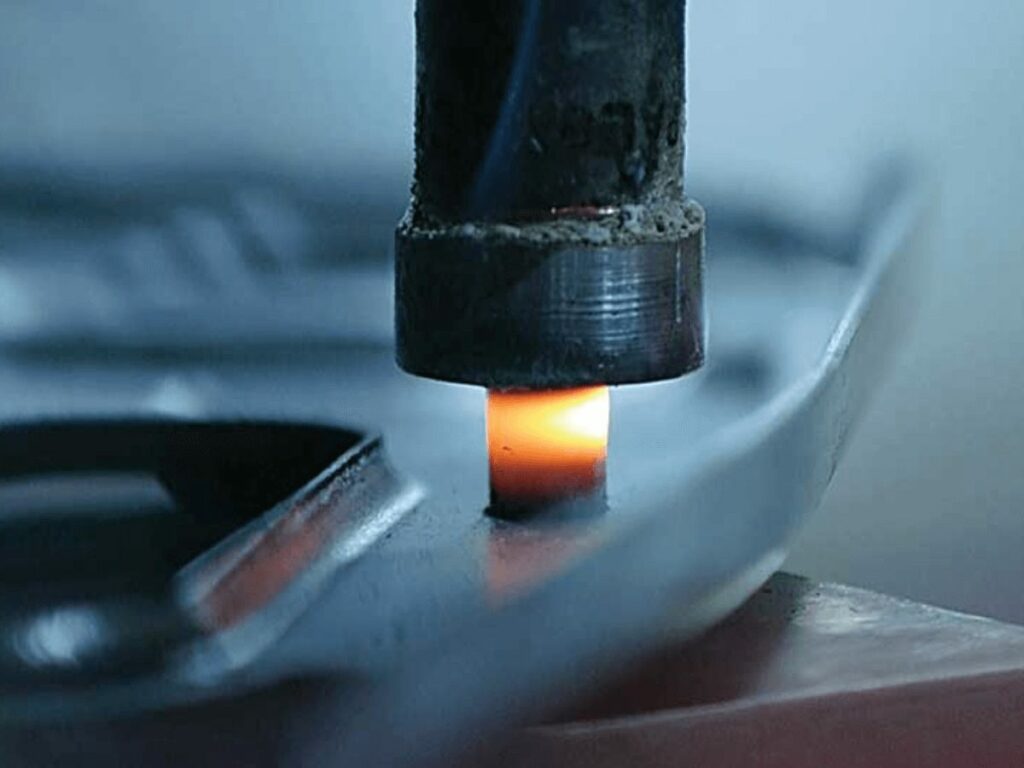

A Hot Riveting Machine is a device used to join two pieces of metal by heating and pressing them together. The machine uses a rivet, which is a short metal pin with a head on one end, to join the two pieces of metal. The rivet is heated until it is red hot, and then it is inserted into the hole in the two pieces of metal with increased hole fill.

The heat from the rivet causes the metal to expand, and the pressure from the machine causes the rivet to sink into the metal. The two pieces of metal are then held together until the rivet cools and hardens. Hot riveting machines are used to join two pieces of metal together, but they cannot be used on materials other than metal.

Hot riveting is not as strong as welding, so hot riveted joints are usually combined with welding for the strongest connections. Hot riveting is common in maintenance work on airplanes or boats because petroleum products can weaken welded joints.

Hot riveting can also be used to repair the metal, but it is more expensive than welding. Hot riveting is usually done by industrial machines that are automated to heat the rivet and set it into motion while the operator simply feeds pieces of metal into it.

Hot riveting machine form a round fastener or orbital forming used for joining together two pieces of metal. Hot riveting can be done by hand or with an automated hot riveting machine.

The intensification valve is a key component of the Hot Riveting Machine. It is responsible for controlling the amount of pressure that is applied to the rivet. The valve is usually adjustable, so you can set the pressure to the desired level. This allows you to get the best results when riveting.

You can use a pressure pad to join two pieces of metal together using a Hot Riveting Machine. Many machines have this so that you can place on top of the workpiece to hold it in place as you insert the rivet into it.

2

Hot Riveting Machine Key Features

The Hot Riveting Machine is a fairly new invention and has many benefits over other types of riveting machines. Some of the key features include:

Joins Metal Quickly and Easily

One of the key benefits of the Hot Riveting Machine is that it joins metal quickly and easily. This means that you can get the job done quickly and efficiently, without having to spend a lot of time and energy trying to join the metal together.

Stainless Steel Hot Rivets for Coupling Metal

One of the perks of using a Hot Riveting Machine is that it comes with stainless steel hot rivets. These rivets are designed to join metal together and can create an incredibly tight grip, making them perfect for coupling metal. Because they use heat, you do not need to worry about them corroding or rusting, meaning that the Hot Riveting Machine is a very durable machine.

No Need for Special Tools or Skills

One of the best things about the Hot Riveting Machine is that you don’t need any special tools or skills to use it. All you need is the machine itself and a few pieces of metal that you want to join together. This makes it a very versatile tool, perfect for a variety of different applications.

Can Be Used With a Wide Range of Materials

The Hot Riveting Machine can be used with a wide range of materials, making it the perfect tool for a variety of different applications. Whether you need to join exotic metals together, or you need to fuse two pieces of plastic or wood, the Hot Upset Riveting Machine can do the job. This makes it a very versatile tool, perfect for any project you might be working on.

Produces a Strong and Durable Joint

The Hot Riveting Machine is a great tool for joining metal together. One of the key benefits of using this machine is that it produces a strong and durable joint. This means that you can rely on the joint to be strong and hold up under pressure applied, making it perfect for a variety of different applications.

Additionally, the Hot Riveting Machine comes with stainless steel hot rivets, which means that you don’t need to worry about them corroding or rusting. This makes the Hot Riveting Machine a very durable machine that can be used with a wide range of materials.

3

Benefits of Using Hot Riveting Machine

There are many benefits to using a Hot Riveting Machine. Some of these benefits include:

Can Be Used for a Variety of Projects

A Hot Riveting Machine is a versatile tool that can be used for a variety of projects. Some of the projects that a Hot Riveting Machine can be used for include:

- Automotive

- Aircraft

- Marine

- Industrial

Each of these industries has different needs, and a custom Hot Upset system can be used to fulfill those needs. For example, in the automotive industry, a Hot Riveting Machine can be used to attach body panels and trim. In the aircraft industry, a Hot Riveting Machine can be used to attach parts of the aircraft together.

Relatively Easy To Use

A Hot Riveting Machine is a tool that is relatively easy to use. All you have to do is insert the rivets into the Hot Riveting Machine, and it will take care of the rest. It is also very easy to adjust the machine so that it is the correct size for the rivets you are using. This makes it easy to use Hot Riveting Machines for a variety of projects.

Provide a Strong, Reliable Bond Between Two Pieces of Metal

When you use a Hot Riveting Machine, you can be sure that you are getting a strong, reliable bond between two pieces of metal. This is because a Hot Riveting Machine uses heat to weld the rivets in place.

This means that the rivets will be able to withstand a lot of stress and pressure applied. Additionally, the weld will be very strong and will not easily break or come undone.

Provide a Cleaner Weld

One of the benefits of using a Hot Riveting Machine is that it provides a cleaner weld. This is because a Hot Riveting Machine uses heat to weld the rivets in place. This means that there is no need for any type of adhesive or sealant. Additionally, the weld will be very strong and will not easily break or come undone.

4

The Difference Between a Hot Riveting Machine and Other Types of Riveting Machine

When it comes to riveting machines, there are several different types that you can choose from. Some of the most common types of riveting machines include:

- Hot Riveting Machine

- Pneumatic Riveting Machine

- Manual Riveting Machine

Each of these machines has its own unique advantage and drawbacks. Here is a brief overview of the differences between a Hot Riveting Machine and other types of riveting machines:

| Hot Riveting Machine | Pneumatic Riveting Machine | Manual Riveting Machine |

|---|---|---|

| Can be used with a wide range of materials | Can be used with a wide range of materials | Only produces a temporary joint, which means it must be done in several different processes |

| Produces a strong and durable joint | Produces a strong and durable joint | Relatively difficult to use |

| Comes with stainless steel hot rivets | Comes with stainless steel rivets that are pneumatic | Comes with several different sizes of rivets, which must be adjusted manually. |

| Relatively easy to use | Relatively easy to use | Can be used to create a clean weld on thin metals, but will not produce the same results as Hot Riveting Machine or Pneumatic Riveting Machine |

| Provides a cleaner weld |

5

When You Should Use a Hot Riveting Machine

A Hot Riveting Machine is an essential tool for many different projects. Here are some times when you should use this machine:

When You Need To Join Two Pieces of Metal Together Firmly

When you need to join two pieces of metal together firmly, a Hot Riveting Machine is the best way to do it. This machine uses heat and pressure to fuse the two metals together, creating a strong bond that will not break.

If you need to join two pieces of metal together, a Hot Riveting Machine is the best way to do it.

When You Need To Create a Tight Seal

A Hot Riveting Machine is specifically designed to create a tight seal between two pieces of metal. This machine uses heat and pressure to join the two pieces together, forming a bond that is incredibly strong.

If you need to create a tight seal between two pieces of metal, a Hot Riveting Machine is the best tool for the job.

When You Need To Fasten Two Pieces of Metal Together

When you need to fasten two pieces of metal together, a hot riveting machine can be a great option. This type of machine uses heat to join the metal pieces together, and it can be a very effective way to create a strong bond.

When You Need To Attach a Metal Object to Another Surface

It can be very difficult to attach a metal object to another surface. This is especially true if the surfaces are not aligned properly. In these cases, a hot riveting machine may be required.

Hot riveting machines use heat to attach metal objects to other surfaces. They are usually used in manufacturing or construction settings.

6

Riveting Process on Using Hot Riveting Machine

The right process on how to hot rivet is relatively simple:

Step #1 Mark the Spot Where You Will Be Joining the Metal Together

Use a permanent marker to write on the surface of the metal, marking where you will be joining it together. This can also include what kind of rivet-to-be goes into the machine.

Step #2 Set Up Your Hot Riveting Machine

It is best to put down a few sheets of newspaper for the hot riveting machine to rest on, as well as any other protective gear you want to make sure it doesn’t get damaged or dirty by oil, water, or other chemicals that may come from the Hot Riveting Machine.

Also, put down a few sheets of newspaper to catch any excess rivets that may fall out when you insert them into the machine or when they are getting hammered down after being joined with the metal.

Step #3 Insert the Rivet Into the Machine

Make sure your Hot Riveting Machine is off, and everything is set up and ready to go before you insert the rivet. Press down on the lever until it hits a stop, then turn the hot rivet press on using the button or setting designed for that Hot Riveting Machine.

The rivet should stay in place as long as it hasn’t been switched into a different setting than what it is required to be on.

Step #4 Put Pressure on the Lever To Join the Metal Together

Once you have inserted the rivet into the Hot Riveting Machine, push down with all your might (but not too hard) onto the lever, keeping balance with your feet if necessary. Do it slowly and carefully so that you can ensure the metal will be joined together.

Step #4 Remove the Rivet From the Machine

Once you bring your Hot Riveting Machine away from the surface of the metal, lift it and hold it steady and still so that you can remove the rivet from being inserted into it.

Make sure to take your Hot Riveting Machine away from any surface before taking the rivet out so as not to accidentally knock it against something and damage your Hot Riveting Machine.

Step #5 Hammer It Down So It’s Flush With the Surface of the Metal

At this point, if you have already taken out your Hot Riveting Machine from where you’re working, use a hammer to hammer the rivet down into the surface of the metal.

If you’ve used a Hot Riveting Machine that is designed to do this automatically, then just pry the hot parts and remove the metal by hand.

Step #6 Clean Up the Area and Dispose of the Rivet

Use paint thinner or some other cleaning liquid to clean up any excess mess and to dispose of the Hot Riveting Machine, if you’re planning on continuing your work. Otherwise, wait until it has cooled down completely before throwing everything in the trash when you are done with it.

7

Hot Riveting Machine Cycle Time

A Hot Riveting Machine Cycle Time is the amount of time it takes for a Hot Riveting Machine to heat up to the point where it can be used to join metal objects together. It is usually a few minutes, but it can vary depending on the Hot Riveting Machine.

The cycle time is important, especially if the machines are being used frequently. Users want the machines that have cycle times of around one minute or less so they would not have to wait long before using them.

Hot Upset typically has a 3-4 second cycle time, which is generally slower than Orbital, Radial or Impact Riveting

8

Hot Riveting Machine Average Price

If you’re in the market for new hot rivet tools machine, you’ll want to know what the average price is. Power consumption and tooling electrodes are included in the cost of ownership.

One of the most common hot riveting machines is a pneumatic riveter. This type of machine uses compressed air to drive the rivets into the workpiece. Pneumatic riveters are available in both handheld and benchtop models. The average price for a pneumatic riveter is around $200.

If you need a larger machine, you can purchase an electric riveting machine. These machines are typically used in manufacturing plants and can cost several thousand dollars. However, they offer more power and speed than a pneumatic rivet gun.

Another Hot Riveting Machine is hydraulic. These machines require oil and water to work properly, which makes them cost more. The average price for a hydraulic Hot Riveting Machine is $8,000 to $10,000. Floor models can be as much as $20,000.

A hot riveting machine that’s manual requires no electricity and is very basic. It uses a handle to squeeze the gun. These Hot Riveting Machines are less commonly used, but they work well for occasional tasks.

9

Where to Find the Best Deals on Hot Riveting Machine

The following is where you can find the Hot Riveting Machine:

Riveth

Riveth is a leading manufacturer of riveting machines and equipment in China. Our company have a mission statement is to be the best Chinese manufacturer of riveting machines by adhering to high-quality standards that guarantee customer satisfaction. For more information Contact us at Rivet Today!

Online

When it comes to finding the best deals on Hot Riveting Machine, you need to determine where to look. The first place to check is online. There are many retailers who sell Hot Riveting Machines, and they often have good deals on them. You can also check auction sites like eBay, where you can find used machines at a discount.

Trade Shows

Another place to find good deals on Hot Riveting Machines is at trade shows. Many companies exhibit their latest machines at trade shows, and you can often get a good deal on one there.

Local Suppliers

Don’t forget to check with your local suppliers. They may not have the latest machines, but they may have older models that are still in good condition and available at a discount.

10

5 Tips Before Using Hot Riveting Machine

When working with a hot riveting tools machine, there are some key things to remember in order to ensure safe and efficient use. Here are some tips to keep in mind:

#1 Always Read the Manufacturer’s Instructions Before Use

When using any Hot Riveting Machine, it is always important to read and follow the manufacturer’s instructions. This will ensure the safe and efficient use of the machine. Failing to do so may result in injury or damage to the machine.

#2 Only Use the Hot Riveting Machine for Its Intended Purpose

When using a Hot Riveting Machine, it is important to only use it for its intended purpose. Failing to do so may result in injury or damage to the machine. Make sure to read and follow the manufacturer’s instructions before using the machine.

#3 Keep the Hot Riveting Machine Clean and Free of Debris

When using a Hot Riveting Machine, it is important to keep the machine clean and free of debris. Failing to do so may result in injury or damage to the machine. Keep hands clean while working with Hot Riveting Machines.

#4 Do Not Over-Tighten Rivets or Bolts

When using a Hot Riveting Machine, it is important not to over-tighten rivets or bolts. Doing so can cause the rivet or bolt to break, which could lead to injury. Always make sure that the rivet or bolt is properly tightened before using the Hot Riveting Machine.

#5 Make Sure the Workpiece Is Properly Clamped in Place Before Use

Before using the Hot Riveting Machine, be sure to clamp the workpiece in place. This will help to ensure accuracy and prevent any mishaps while riveting.

Here’s a quick video on how Hot Riveting Machine works:

11

Final Words

Hot riveting machines are the perfect solution to your metal joining business. They can be used on steel, aluminum, and stainless steel. You can also use them to join dissimilar metals together. And they’re available in many different sizes.

If you want a strong connection that will hold up under pressure, then hot riveting is definitely what you need! So if you’re looking for an effective way to join two pieces of metal together, then look no further than our hot riveting machines!

Click this website right now and find out more about our hot riveting machines and other new products!

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.