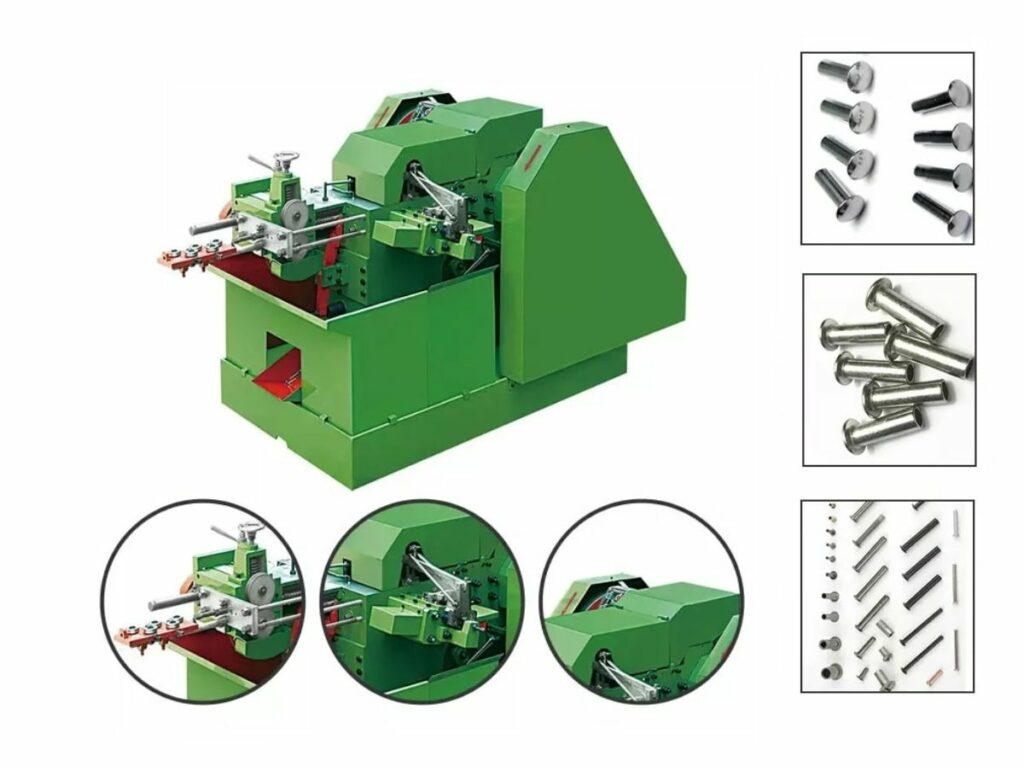

PRODUCT FEATURES

Aluminum Rivet Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

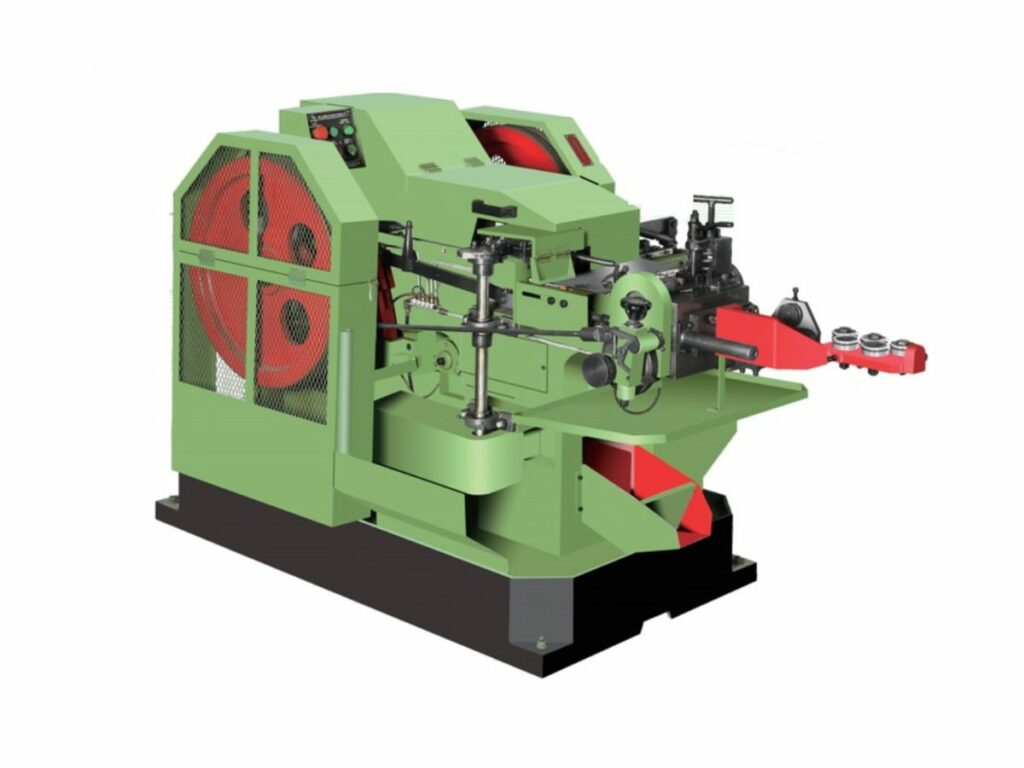

Aluminium Rivet Machine

The riveting machine is a device that is used to manufacture aluminum wheels, it’s the first and only one of its kind. It can be adjusted easily and has an efficient design that makes the process easier than ever before.

The machine also has durable parts that are made from high-quality materials. This helps to make sure you don’t have to worry about replacing parts or having issues with your product in the future.

Table of contents

1

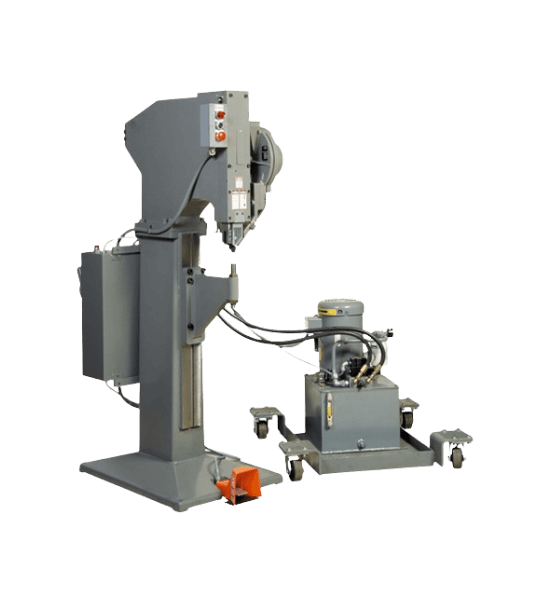

Aluminium Rivet Machine Definition and What Does It Do

An aluminium rivet machine is a device used to join two pieces of aluminium together by driving a rivet through the pieces. The rivet is a metal pin with a head on one end and a shank on the other.

The head is mushroom-shaped and larger in diameter than the shank. When the rivet is driven through the pieces, the shank is deformed so that it expands and grips the sides of the holes.

The aluminium rivet machine consists of the following parts:

- Base – The base is mounted on a workbench and it holds the column in place.

- Column – The column supports the headstock and the tailstock.

- Headstock – The headstock has a chuck that holds the aluminium rivet shank while the aluminium rivet machine is being driven.

- Tailstock – The tailstock supports the other piece of aluminium during joining operations.

The aluminium rivet machine works by heating the rivet until it is soft, then placing it in the groove on the top of the machine. The two pieces of metal to be joined are then placed underneath the machine.

Then the lever is pulled down, pushing the rivet into the groove and bonding the two pieces of metal together. Riveters vary in size and construction, but all have a chuck to hold the aluminium rivet shank and a mechanism to rotate the aluminium rivet before it is driven into one or both pieces of aluminium.

The aluminium rivet shank is normally made of aluminum but other materials, such as steel or brass, are also used.

2

Aluminium Rivet Machine Key Features

The aluminium rivet machine is one of the most popular types of riveting machines on the auto body repair applications market. It is a reliable machine that is perfect for a variety of riveting applications.

Some of the key features of the aluminium rivet machine include:

Versatility

The aluminium rivet machine is versatile and can be used for a variety of riveting applications, including:

- Joining Metal Sheets

- Securing Panels and Covers

- Fastening Hinges

- Repairing or Reinforcing Metal Parts

Strength

The aluminium rivet machine is strong, and can easily handle heavy loads. It is perfect for securing panels and covers, joining metal sheets using its three additional rivet heads, and fastening hinges.

Durability

The aluminum rivet machine is long-lasting and capable of withstanding repeated use.

Long-Lasting

The aluminum rivet machine is built to last and will remain in good shape for an extended period of time.

Ease of Use

The aluminum rivet machine is simple to operate and may be utilized by individuals who have had just rudimentary training.

3

Benefits of Using Aluminium Rivet Machine

The aluminium rivet machine has many benefits that make it a valuable tool for any workshop. Some of the key benefits include:

Versatility

The aluminium rivet machine can be used to join a variety of materials, including aluminium, brass, copper, steel and plastic. This makes it a versatile tool that can be used for a variety of tasks.

Strength

The aluminium rivet machine creates a strong joint that is resistant to pulling and twisting forces. This makes it ideal for applications where strength is important.

Efficient

The aluminium rivet machine can achieve fast cycle times, which means that it can quickly join multiple parts together. This makes it an efficient way to work.

Productivity

The aluminium rivet machine can operate unattended, which means that it can be left to perform a task without supervision or assistance. This makes it productive because it doesn’t need constant monitoring and restarting.

4

The Difference Between an Aluminium Rivet Machine and Other Types of Rivet Machine

When it comes to riveting machines, there are many different types available on the market. However, the main difference between an aluminium rivet machine and other types of rivet machines is that an aluminium rivet machine uses aluminium rivets.

Aluminium rivets are a popular choice for many industrial applications because they are strong and durable. Another type of rivet machine includes a hand riveter. A hand riveter is a handheld device that the aluminium rivets are inserted into.

This allows for aluminium rivets to be securely fastened in place when pressure is applied by squeezing the aluminium handles together. It also makes it easy to carry around since it’s small and lightweight.

Aluminium rivet machines are commonly used in aluminium fabrication. Aluminium is a material that can be easily molded into any shape, and aluminium fabrication is the process of shaping aluminium into different applications such as screws, bolts, and nuts.

5

When You Should Use Aluminium Rivet Machine

When riveting aluminium, you should use an aluminium rivet machine. The aluminium rivet machine is specifically designed to fasten aluminium rivets, which makes the process much more efficient and easier than using a standard riveting tool.

There are many times when you might need to use an aluminium rivet machine. Here are a few occasions when it is especially handy:

- When you need to join two pieces of metal together securely.

- When you need to create a strong, durable bond.

- When you need to keep your project looking neat and professional.

- When you need to increase your speed.

- When aluminium is the best choice for your project’s needs.

6

Step by Step Guide on Using Aluminium Rivet Machine

When it comes to riveting aluminium, there’s no need to worry – the process is simple. With the right aluminium rivet machine, any homeowner can complete this task with ease.

Step #1 Select the Type of Rivet

Begin by selecting the aluminium rivets that you’ll be using for your project. Make sure to choose a rivet that is slightly smaller than the hole in the aluminium sheet you’re working with.

Step #2 Insert the Rivet Into the Machine

Next, insert the rivet into the aluminium rivet machine. You’ll want to make sure that the head of the rivet is facing up, and that the stem is sticking out of the bottom of the machine.

Step #3 Hold the Aluminium Sheet Into Place

Now, hold the aluminium sheet in place and squeeze the handles of the rivet machine together. This will cause the rivet to be inserted into the hole in the aluminium sheet.

Step #4 Apply Pressure on the Handle of the Machine

Apply pressure to the handle of the machine, and make sure to hold it down until the rivet is fully inserted into the aluminium material.

Step #5 Release the Pressure

Finally, release the pressure on the handles and allow the aluminium rivet machine to release the stem from the rivet.

Step #6 Repeat the Process

Repeat this process until you have aluminium rivets inserted into all the holes in your aluminium sheet.

Step #7 Let the Aluminium Rivets Cool Down

Once completed, allow the aluminium rivets to cool for five minutes before using them. If you don’t wait long enough, the aluminium might not hold up well when used for its intended purpose.

7

Aluminium Rivet Machine Average Price

An aluminium rivet machine is a specialized tool used in the manufacturing industry to join pieces of aluminium together. The average price for an aluminium rivet machine can vary depending on the features and specifications of the machine.

However, most machines will range in price from around $2,000 to $10,000. It is important to consider the features of the aluminium rivet machine before making a purchase.

Some factors to consider include the size of the machine, the type of rivets it can use, and the power source. Machines that are larger or can use a wider variety of rivets tend to be more expensive.

Likewise, machines that are powered by electricity rather than air pressure are generally more expensive.

8

Where to Find the Best Deals on Aluminium Rivet Machine

When looking for a good aluminium rivet machine, it’s important to do your research and find the best deal. Here are some places where to find the best deals:

Online Retailers

Online retailers often have great deals on aluminium rivet machines. Be sure to compare prices and read reviews to find the best machine for your needs.

Local Stores

Local stores may not have the best prices on aluminium rivet machines, but they often offer great service and support. If you have any questions or problems with your machine, the staff at a local store will be more likely to help you out.

Factory Outlets

Factory outlets are a great place to find discounted aluminium rivet machines. Be sure to check the quality and warranty of any aluminium rivet machine you buy at a factory outlet.

Manufacturer

Most aluminium rivet machine manufacturers like Riveth offer special discounts and promotions to customers who shop directly with them. Be sure to check out aluminium rivet machine manufacturer websites for current offers.

9

10 Tips Before Using Aluminium Rivet Machine

When using an aluminium rivet machine, there are a few things you can do to ensure the process goes smoothly. Here are ten tips to help you get the most out of your aluminium rivet machine:

| No. | Tips |

|---|---|

| 1 | Make Sure It’s the Right Size |

| 2 | Check the Power Source |

| 3 | Check the Alignment of the Rivet |

| 4 | Check the Aluminium Sheet for Sharp Edges |

| 5 | Use a Clean Aluminium Sheet |

| 6 | Keep the Machine Clean |

| 7 | Lubricate Parts Regularly |

| 8 | Keep Your Hands Away From Moving Parts |

| 9 | Make Sure You Press the Gun Evenly |

| 10 | Keep the Rivets in Their Original Packaging |

#1 Make Sure It’s the Right Size

Aluminium rivets come in a variety of different sizes, so it’s important to make sure you’re using the right size rivets for your aluminium rivet machine. If the rivets are too small, they may not be able to hold the aluminium sheet together properly. If the rivets are too large, they may not fit into the holes in the aluminium sheet.

#2 Check the Power Source

Make sure the aluminium rivet machine is plugged into an outlet and has enough power to run properly. If the machine is powered by air pressure, make sure there is enough air pressure available to run it.

#3 Check the Alignment of the Rivet

Before inserting the rivet into the aluminium sheet, check to make sure that the head of the aluminium rivet is centered in the aluminium sheet. This will help you avoid problems when you’re trying to force the aluminium rivet into position.

#4 Check the Aluminium Sheet for Sharp Edges

The aluminium sheet should be completely free of sharp edges and protrusions. Any aluminium sheet with sharp aluminium edges will damage the aluminium rivet heads and may damage the aluminium rivet machine as well.

#5 Use a Clean Aluminium Sheet

The aluminium sheet should be free of dirt and debris before you use it, otherwise, it can get caught in the aluminium rivets or aluminium rivet machine. If aluminium rivets are too dirty, they may not be able to hold aluminium sheets together.

#6 Keep the Machine Clean

Check the condition of the rivet gun and make sure it is clean and free of oil or grease.

#7 Lubricate Parts Regularly

Lubricate the jaws of the rivet gun with a light layer of oil before use. This will help to keep the aluminium rivets from sticking in the gun.

#8 Keep Your Hands Away From Moving Parts

It’s important to keep your hands clear of the moving parts of the aluminium rivet machine while it’s in use. If your hands come into contact with the moving parts, you could get injured.

#9 Make Sure You Press the Gun Evenly

Make sure you press the aluminium rivet gun evenly and at a constant speed when squeezing. If you don’t, you could cause damage to aluminium rivet machine.

#10 Keep the Rivets in Their Original Packaging

Keep aluminium rivets in original packaging when they’re not being used. This will help to protect the aluminium rivets from getting damaged and ensure they last a long time.

To know more about the basic riveting fundamentals, watch this video.

10

Conclusion

Aluminium rivet machines are a great way to aluminium sheet quickly and easily. However, these aluminium rivet machines can be expensive pieces of equipment.

Before you buy an aluminium rivet machine, it’s important to do your research to make sure you’re getting the aluminium rivet machine that’s right aluminium sheet for your needs. Contact us to get started!

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.