PRODUCT FEATURES

Automatic Riveting Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Automatic Riveting Machine: A Definitive Guide

The automatic riveting machine offers greater consistency, productivity, innovative concept & modern manufacturing techniques. But it’s hard to make a decision when purchasing such a machine.

Worry no more because here, we’ll discuss what they are, how they work, and some of the key features to consider when making your purchase. Plus, we’ll provide a few recommendations to help get you started.

So whether you’re a wholesaler or small business owner, by the end of this post, you’ll know exactly which machine is suitable for you. So read on to learn more!

Table of contents

1

What Is an Automatic Riveting Machine

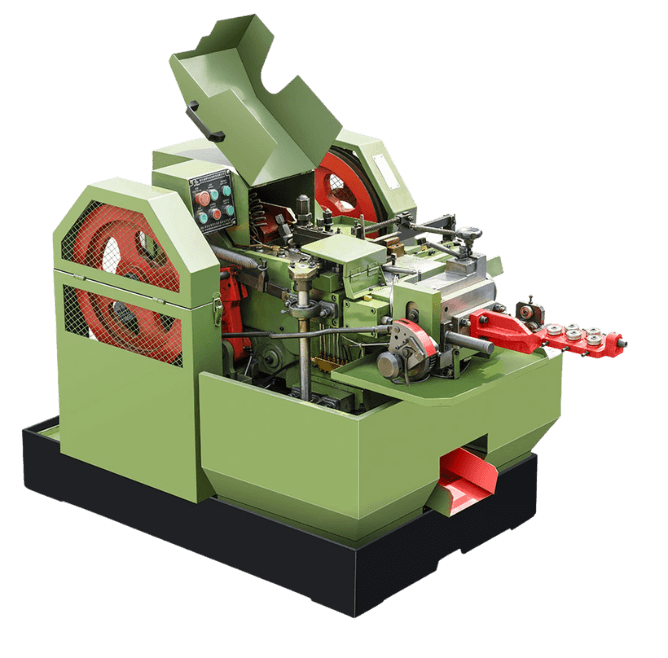

An automatic riveting machine is a device that attaches rivets to metal parts. It is a mechanized process that uses a pneumatic or hydraulic system to drive the rivet into the part.

The automatic riveting machine can join two pieces of metal together or attach a metal part to a substrate or forming tool. The automatic riveting machine has several advantages and more control over manual feed riveting machines.

First, it is much faster than manual riveting. Second, it can produce more consistent results than manual riveting. Third, it requires less skill to use than manual riveting. Fourth, it can be used to join parts of different sizes and shapes.

Finally, it can be used to join parts that are difficult to reach with a manual riveting tool. Overall, the automatic riveting machine is a versatile and efficient tool for joining metal parts.

An operator can save time and produce consistent results. If you need to join metal parts, an automatic riveting machine is the best option.

2

Benefits of an Automatic Riveting Machine Over Traditional Riveting Methods

When it comes to automatic pneumatic riveting machine, there are a few different methods that can be used. One of the most popular methods is the traditional riveting method.

However, there is a newer and more advanced method that has been gaining in popularity in recent years: the automatic riveting machine. Several benefits come with using an automatic riveting machine over the traditional method, and these benefits include:

Time Efficient

The first benefit is time savings. An auto feed riveting machine or automatic rivet machine can do the work of several people or operators, which means that your project will be completed much faster.

Accurate

Additionally, the drivematic riveting machine or orbital riveting machine is much more accurate than traditional riveting methods, meaning that there is less chance of mistakes being made. This leads to fewer wasted materials and a higher quality finished product.

Efficient

Finally, automatic industrial riveting machines are more efficient and require less manpower than traditional methods. This means that you can save both time and money when using an automatic riveting machine.

If you’re looking for a faster, more accurate, and more efficient way to rivet your products, then an automatic riveting machine may be the perfect option for you.

3

How Does an Automatic Riveting Machine Work

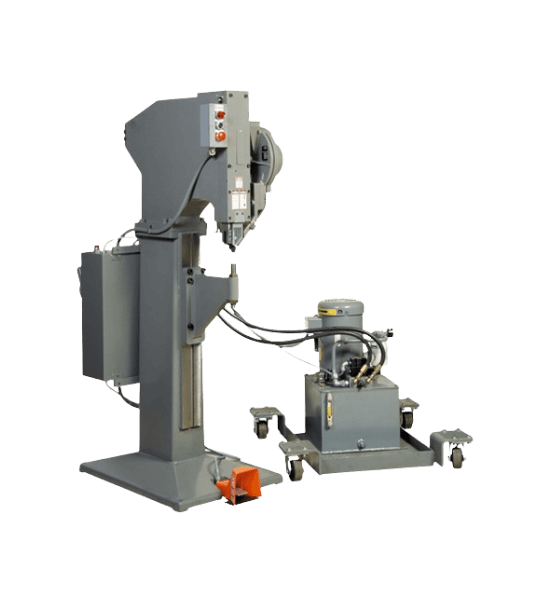

An automated riveting machine is a model or device that uses a pneumatic or hydraulic system to drive the rivet into the workpiece. The machine consists of a base, feed track, a rivet head, and a rivet arm.

The rivet head is mounted on the end of the rivet arm, and the arm is attached to the base. The rivet is fed into the head and the arm moves down, forcing the rivet into the workpiece.

There are many different types of automatic riveting machines in the industry, but they all have the same basic components. The first is a base that has the arm attached to it.

This can be made out of metal or plastic, depending on what type of automatic riveter you choose. Next, you will need a workpiece that has holes drilled in it to accept the rivets.

The rivet head is then attached to the end of an arm and this arm will move down onto the workpiece, forcing the rivet into place. The automatic riveting machine uses a pneumatic or hydraulic system to drive the rivet into the workpiece.

This automation or system is powered by compressed air or hydraulic fluid, and this is what drives the automatic riveting machine. The automatic riveter uses a pneumatic or hydraulic system to drive the automatic rivet into the workpiece.

4

Different Types of Automatic Riveting Machines

There are four different types of automatic riveting machines: vertical, horizontal, automatic turret, and semiautomatic. Listed below are their characteristics to further understand each rivet machine.

Vertical Automatic Riveting Machine

The most common type is the vertical automatic riveting machine. It is a versatile machine that can be used for a variety of applications.

Horizontal Automatic Riveting Machine

The horizontal automatic riveting machine is typically used for heavy-duty applications because it has more power than the other types of automatic riveting machines.

Automatic Turret Automatic Riveting Machine

The automatic turret automatic riveting machine is ideal for high-volume production because it can produce rivets quickly and efficiently.

Semiautomatic Riveting Machine

The semiautomatic riveting machine is the least expensive and simplest type of automatic riveting machine. It is ideal for small-scale production or prototype work.

Which type of automatic riveting machine is best for your application? That depends on the type of rivets you need to produce and the amount of production you need to achieve.

One of the most reputable automatic riveting machine manufacturers is Riveth, do contact their team for assistance to determine which machine is right for you.

5

How To Choose the Right Automatic Riveting Machine for Your Needs

When it comes to automatic riveting machines, there are a few things you need to consider before making a purchase. Here are some tips to help you choose the right machine for your needs:

Type of Machine

What type of rivets will you be using? Automatic riveting machines come with different die sets and construction so make sure you choose one that is compatible with the rivets you’ll be using.

Size of Rivets

What size rivets do you need? Automatic riveting machines come in different sizes, so make sure you choose one that can handle the size of rivets you’ll be using.

Budget

What is your budget? Automatic riveting machines can range in price, so make sure you choose one that fits your budget.

Automatic riveting machines are an excellent investment if you’re looking for a way to speed up your production process. There are many different models available, so make sure you do some research before making a purchase decision.

6

Materials That Can Be Riveted With a Machine

Examples of materials that can be riveted with a machine include metal, plastic, and other materials. There are a variety of machines that can be used for riveting, including automatic riveting machines.

Riveting is a process that uses metal or plastic pins to join two pieces of material together. The rivets are inserted into the materials and then hit with a hammer, which causes them to expand and hold the materials together.

Riveting can be used to create strong joints in a variety of materials. There are a variety of materials that can be riveted with a machine. Some of these materials include aluminum, brass, copper, steel, and titanium.

The most common types of rivets are solid rivets and tubular rivets. Tubular rivets are typically used on materials that are thin, such as sheet metal. Solid rivets are more commonly used on thicker materials.

It is crucial to understand what are the materials that you will be using in utilizing this machine. If not properly determined, their differences in their length, position, sizes, and more may cause damage or accident.

7

6 Tips for Proper Use and Maintenance of an Automatic Riveting Machine

An automatic feed riveting machines are a type of machine that uses a ram to drive a rivet into the workpiece. There are several tips for proper use and maintenance of this type of machine:

| No. | Tips |

|---|---|

| 1 | Make Sure The Machine Is Properly Calibrated |

| 2 | Lubricate The Machine Regularly |

| 3 | Keep The Machine Clean |

| 4 | Inspect All Rivets Before Use |

| 5 | Use The Correct Type Of Rivet |

| 6 | Do Not Overwork The Machine |

#1 Make Sure The Machine Is Properly Calibrated

Make sure the rivet machines are gradually lowered properly calibrated before use. This will ensure that the rivets are driven into the workpiece or holes with the proper force.

#2 Lubricate The Machine Regularly

Lubricate all moving parts of the machine regularly. This will help reduce friction and wear. It will also allow you to check the machine because sometimes the parts like hand lever or the machine is equipped with rust.

#3 Keep The Machine Clean

Keep the machine clean and free of debris. This will help prevent damage and keep the machine running smoothly.

#4 Inspect All Rivets Before Use

Inspect all rivets for proper fit before use. Improperly fitted rivets can cause damage to the workpiece or the machine itself.

#5 Use The Correct Type Of Rivet

Use the correct type of rivet for the job at hand. Using the wrong type of rivet can damage the machine or the workpiece.

#6 Do Not Overwork The Machine

Do not force the machine to do more than it is capable of. This can result in damage to the machine tools or the workpiece.

Following these tips will help ensure that your automatic riveting machine operates safely and efficiently.

8

Steps on How To Purchase an Automatic Riveting Machine From China

When looking to purchase an automatic riveting machine, China is often a good place to start. This country is not just known for quality leather goods but machines as well. There are a few things to keep in mind when making this purchase, however.

Below are some steps on how to make the process as smooth as possible.

Step#1 Make Sure You Know What Type of Machine You Need

Make sure you know what type of automatic riveting machine you need. There are a few different types available, so be sure to do your research ahead of time.

Step#2 Find a Supplier With the Best Price

Once you know what type of machine you need, find a supplier that can provide you with the best price. There are many suppliers located in China, so it shouldn’t be too difficult to find one that meets your needs.

Step#3 Ask the Supplier for Reviews From Past Clients

Be sure to ask the supplier for references or reviews from past customers. This can help you to get a better idea of the quality of the machine they are selling.

By following these tips, you should be able to purchase an automatic riveting machine from China without any problems. If you have any more questions don’t hesitate to contact the Riveth team for assistance.

9

Conclusion

If you’re in the market for an automatic riveting machine, we hope this guide has helped you in making your decision. We’ve provided descriptions of what they are, how they work, and some key features to consider when making a purchase.

This way, whether you’re a wholesaler or small business owner, you’ll know exactly which machine is suitable for you! Contact us and we will do our best to explain more details to you and answer any questions about these machines.

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.