PRODUCT FEATURES

Brake Lining Riveting Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

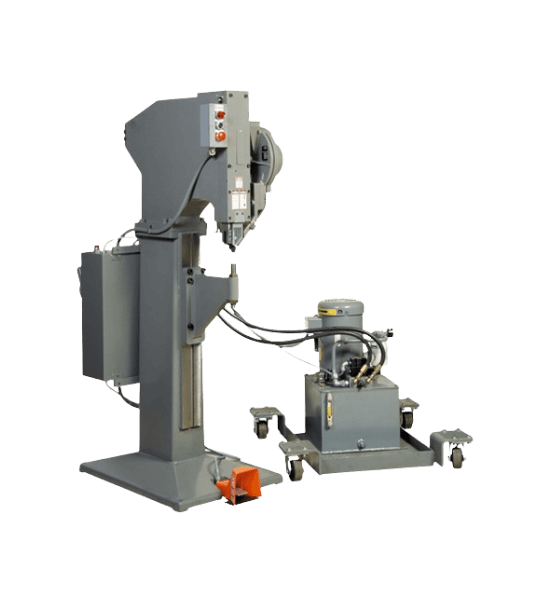

Brake Lining Riveting Machine

This machine can be used to rivet brake lining. It is made of high-quality material and will not rust, which ensures its long life. It is easy to operate and control, which makes it perfect for heavy-duty applications. The riveting speed is adjustable and the operation mode is simple.

The machine has a high production rate with a low failure rate; it will not break down easily because of its quality material and advanced technology. This machine is used to rivet brake linings. It can be used for both hydraulic brake shoe riveting machine and hydro pneumatic riveting machine for brake shoe.

The machine has an adjustable pressure regulator that allows you to choose the force with which you want to push the lining into place. With this machine, you can save much time and energy in your work!

Table of contents

1

Uses of Brake Lining Riveting Machine

A brake lining riveting machine is a tool that is used to fasten brake linings to brake drums or brake discs. This is done by using a series of small, sharp rivets.

There are many different reasons why you might need to use a brake lining riveting machine. Some of the most common reasons include:

To Replace a Brake Lining That Has Been Damaged

If your brake lining has been damaged, you will need to replace it. This can be a difficult task if you do not have the right tools. A brake lining riveting machine is one of the most important tools that you will need for this job.

To Install a New Brake Lining

If you need to install a new brake lining, you will need to use a brake lining riveting machine. This tool is used to fasten brake linings to brake drums or brake discs. It is important to use a brake lining riveting machine when installing a new brake lining, as it will help to ensure that the brake lining is secure.

To Repair a Brake System

If you are in need of brake repair, the best way to do so is by using a brake lining riveting machine. This tool is used to fasten brake linings to brake drums or brake discs. If your brake lining has been damaged, you will need to replace it. This can be a difficult task if you do not have the right tools.

The Riveting Machine Brake Shoe is usually used in a brake shoe factory which is a brake shoe grinding machine, brake shoe riveting machine, and brake shoe brake lining rivet press.

2

Benefits of Using a Brake Lining Riveting Machine

A brake lining riveting machine is a tool that is used to fasten brake linings to brake drums. This is done by using a series of rivets to attach the brake lining to the brake drum.

There are a number of benefits to using a brake lining riveting machine, including:

Increased Safety

When the brake pads wear down, brake linings become exposed and can cause damage to the brake drum if left unchecked.

Better Performance

Brake lining riveting machines allow for more effective brake lining replacement by reducing friction between brake pads and brake drums.

Less Maintenance

Less time spent on maintenance tasks such as changing out worn brake linings.

Cost-Effective

Lower cost of brake riveting machine replacement in the long run.

3

7 Tips on How To Maintain a Brake Lining Riveting Machine

A brake lining riveting machine is a key piece of equipment in a riveting brake linings manufacturing plant. It is important to keep this machine in good condition so that it can produce high-quality brake linings.

Here are some tips on how to maintain a brake lining riveting machine:

| No. | Tips |

|---|---|

| 1 | Keep the Machine Clean and Free of Debris |

| 2 | Keep the Oil Level in the Hydraulic System at the Correct Level |

| 3 | Check the Brake Pads and Brake Shoes Regularly and Replace Them if Necessary |

| 4 | Make Sure the Hydraulic System Is Properly Pressurized |

| 5 | Keep the Electrical System in Good Condition |

| 6 | Keep the Battery Charged |

| 7 | Check the Fuses and Replace Them if Necessary |

#1 Keep the Machine Clean and Free of Debris

One of the most important things you can do to maintain a brake lining riveting machine foot operated is to keep it clean and free of debris. Make sure to clean the machine regularly, and remove any build-up of oil or grease. You should also check for any loose or broken parts, and repair or replace them as needed.

#2 Keep the Oil Level in the Hydraulic System at the Correct Level

One of the most important things you can do to maintain a brake lining riveting machine is to keep the oil level in the hydraulic system at the correct level. If the oil level is too low, the machine may not work properly. If the oil level is too high, it may cause damage to the machine. Make sure to check the oil level regularly, and add or remove oil as needed.

#3 Check the Brake Pads and Brake Shoes Regularly and Replace Them if Necessary

It is important to check the brake pads and brake shoes regularly on a brake lining riveting machine. If the brake pads or brake shoes are worn out, they should be replaced. Worn brake pads and brake shoe rivet machine can cause the machine to work improperly, and may even damage the machine. Make sure to check the brake pads and brake shoes regularly, and replace them if necessary.

#4 Make Sure the Hydraulic System Is Properly Pressurized

One of the most important things you can do to maintain a brake lining riveting machine is to make sure the hydraulic system is properly pressurized. If the hydraulic system is not properly pressurized, the machine may not work properly. Make sure to check the hydraulic system regularly, and adjust the pressure as needed.

#5 Keep the Electrical System in Good Condition

One of the most important things you can do to keep the electrical system in good condition is to keep the wiring clean and free of debris. Make sure to clean the wiring regularly, and remove any build-up of oil or grease. You should also check the brake riveting machine for any loose or broken parts, and repair or replace them as needed.

#6 Keep the Battery Charged

It is important to keep the battery charged on the electrical system. If the battery is low, it may not be able to provide power to the machine. Make sure to charge the battery regularly, and replace it if necessary.

#7 Check the Fuses and Replace Them if Necessary

It is important to check the fuses on the electrical system regularly and replace them if necessary. If a fuse is blown, it may not be able to provide power to the machine. Make sure to check the fuses regularly, and replace them if necessary.

These are some tips on how to maintain a brake liner riveting machine. By following these tips, you can keep your brake lining riveting machine in good condition and ensure that it produces high-quality brake linings. Contact us today at Riveth for more information!

4

Different Types of Brake Lining Riveting Machines

There are several brakes lining riveting machines that you can purchase from brake equipment suppliers. They include:

Air-Powered Brake Riveting Machine

An air-powered brake riveting machine is a brake lining riveting machine that uses compressed air to power the riveting process. This type of brake riveting machine is typically used in industrial applications where large quantities of brake linings need to be riveted.

The air-powered brake riveting machine is a relatively simple machine that consists of a few main components. The main component is the air compressor, which supplies compressed air to the machine. The air is then channeled to the brake riveting head, which performs the riveting operation.

Electric Brake Riveting Machine

An electric brake riveting machine is a brake lining riveting machine that uses electricity to power the riveting process. This type of brake riveting machine is typically used in smaller industrial applications or in brake repair shops.

The electric brake riveting machine is a more sophisticated machine than the air-powered brake riveting machine. It consists of several main components, including:

- Electric Motor

- Gearbox

- Brake Riveting Head

The electric motor powers the gearbox, which in turn powers the brake riveting head. This allows the brake riveting head to perform the riveting operation with greater precision and accuracy.

Pneumatic Brake Riveting Machine

The pneumatic brake shoe riveting machine is a relatively simple machine that consists of a few main components. The main component is the air compressor, which supplies compressed air to the machine. The air is then channeled to the brake riveting head, which performs the riveting operation.

5

5 Tips on How To Choose the Right Brake Lining Riveting Machine for Your Needs

When it comes to brake lining riveting machines, there are a lot of factors you need to consider in order to make the right purchase. Here are some tips to help you choose the right brake lining riveting machine for your needs:

#1 Size of the Machine

First, consider the size of the brake lining riveting machine. Make sure it’s big enough to handle the size of brake lining you need to rivet.

#2 Power of the Machine

Second, consider the power of the brake lining riveting machine. Make sure it has enough power to get the job done.

#3 Features of the Machine

Third, consider the features of the brake lining riveting machine. Make sure it has all the features you need to get the job done.

#4 Price of the Machine

Fourth, consider the price of the brake lining riveting machine. Make sure it’s within your budget.

#5 Reputation of the Manufacturer

Finally, consider the reputation of the brake lining riveting machine manufacturer. Make sure they are a reputable company with a good track record.

By following these tips, you should be able to choose the right brake lining riveting machine for your needs.

6

Cost of a Brake Lining Riveting Machine

The brake lining riveting machine is an important part of the brake system. It attaches the brake lining to the brake drum. The cost of a brake lining riveting machine can vary depending on the type and brand of machine you buy. You can expect to pay anywhere from $500 to $2000 for a quality brake lining riveting machine.

7

Where To Buy a Brake Lining Riveting Machine

There are a few brakes lining riveting machines on the market these days. So, it can be tough to decide which one to buy. You want to make sure that you get a machine that is going to be durable and of high quality.

Riveth

Riveth is a brake lining riveting machine that is quickly gaining a reputation for being one of the best on the market. It is made with high-quality materials and is built to last. Riveth is also very easy to use, making it perfect for anyone who wants to rivet brake linings.

Online Retailers

If you are looking to buy a brake lining riveting machine online, there are a few reputable retailers that you can choose from. Some of the more popular ones include Amazon and eBay.

When shopping on these websites, be sure to read the reviews before making your purchase. This will give you an idea of what others thought of the machine and if it is a good fit for your needs.

Local Hardware Stores

If you are looking to buy a brake lining riveting machine locally, there are likely several hardware stores in your area that carry them. However, the selection may be limited. So, it’s important to do some research before heading out to the store.

You can always call ahead and ask if they have brake lining riveting machines in stock. If not, you can ask to be put on a waiting list so that when one does come in, they will give you a call.

8

Common Issues With Brake Lining Riveting Machines and How To Solve Them

Issues with brake lining riveting machines can cause a lot of headaches for operators. Here are some of the most common problems and how to solve them:

Machine Not Feeding the Brake Lining Properly

This can often be caused by a dirty brake lining or a machine that is not properly calibrated. Make sure to clean the brake lining and check the calibration settings on the machine

Rivets Not Seating Properly

Rivets that don’t seat properly can often cause brake failure. Make sure the brake lining is inserted into the machine properly and that the rivet gun is adjusted correctly.

Improperly Sized Rivets

Using the wrong size rivet can often cause problems with brake performance. Make sure to use the correct size rivet for your brake lining.

These are just a few of the most common issues with brake lining riveting machines. By following these simple tips, you can help keep your machine running smoothly and prevent any costly brake failures. For more information on brake lining riveting machines, contact the experts at Riveth!

Here a video on How to use Brake Lining Riveting Machine:

9

Final Words

If your current machine isn’t working, it might be time to upgrade. This brake lining riveting machine is made of high-quality material and is easy to operate and control. It also has a high production rate with a low failure rate, which makes it perfect for heavy-duty applications.

You can choose the force (pressure) in which you want to push the lining into place using an adjustable pressure regulator, so this brake lining riveting machine will work perfectly for your needs!

Order your new brake lining riveting machine from Riveth today by clicking this link we offer free shipping!

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.