PRODUCT FEATURES

Button Rivet Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Button Rivet Machine

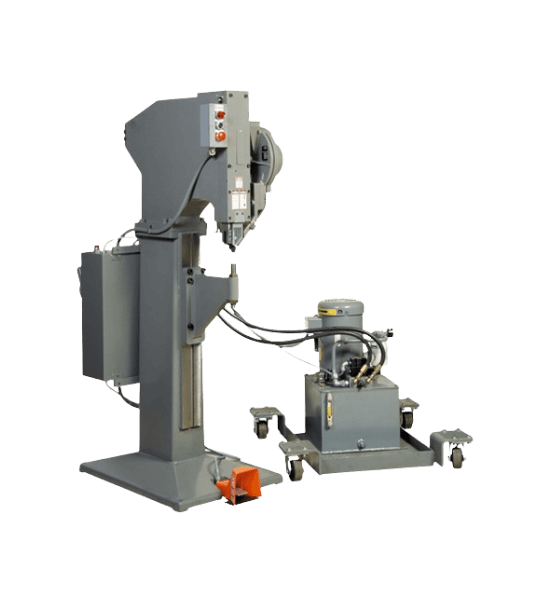

Looking for a strong, durable, and easy-to-use rivet machine? Look no further than the Button Rivet Machine. This machine is perfect for both home and industrial use and can handle a wide range of riveting jobs.

With its simple design and sturdy construction, the Button Rivet Machine is a must-have for any DIY or professional workshop.

The Button Rivet Machine is also great for professional seamstresses who need a quick way to add buttons to their garments. You can use this riveting tool with any type of button you want, including metal buttons with shanks or flat-back plastic ones.

Table of contents

1

Button Rivet Machine Definition and What Does It Do

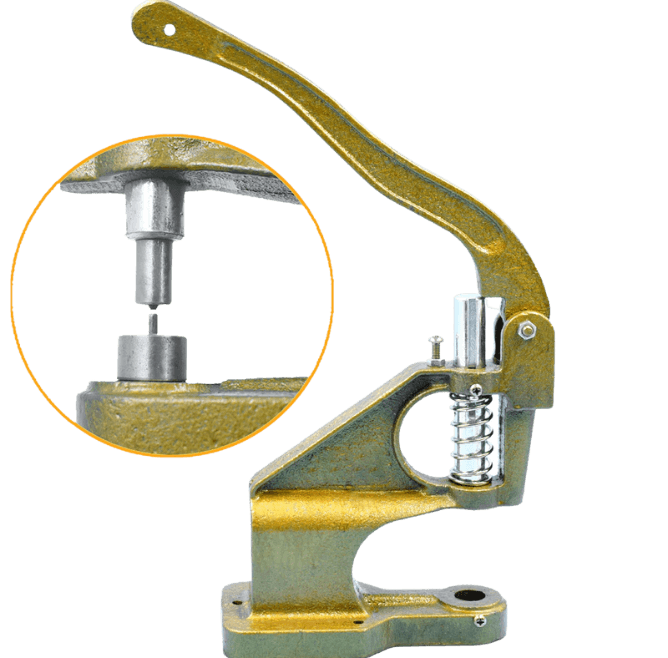

A button rivet machine is used to join two pieces of metal or other sturdy materials together using a button-shaped rivet that has been inserted into punching holes that have been drilled through them. The button-shaped rivet has a head on one side and a tail on the other and is usually made from brass or copper.

The rivet button machine consists of a hydraulic or pneumatic cylinder, which is used to drive the button-shaped rivet through the materials being joined. The head of the button-rivet is placed in a die set attached to the cylinder, and the tail is inserted into a hole in the other piece of material.

When the cylinder is activated, it drives the button-rivet through the materials, forcing the head to expand and form a tight seal against the hole in the material. The button-shaped rivet is then ejected, leaving both materials securely fastened together.

2

Button Rivet Machine Key Features

A button rivet machine is a great option for those looking for an easy and efficient way to join pieces of material together. This rivet hand press machine is perfect for joining thin pieces of metal together, and it can be used for both industrial and DIY applications.

Some of the key features of the button rivet machine include:

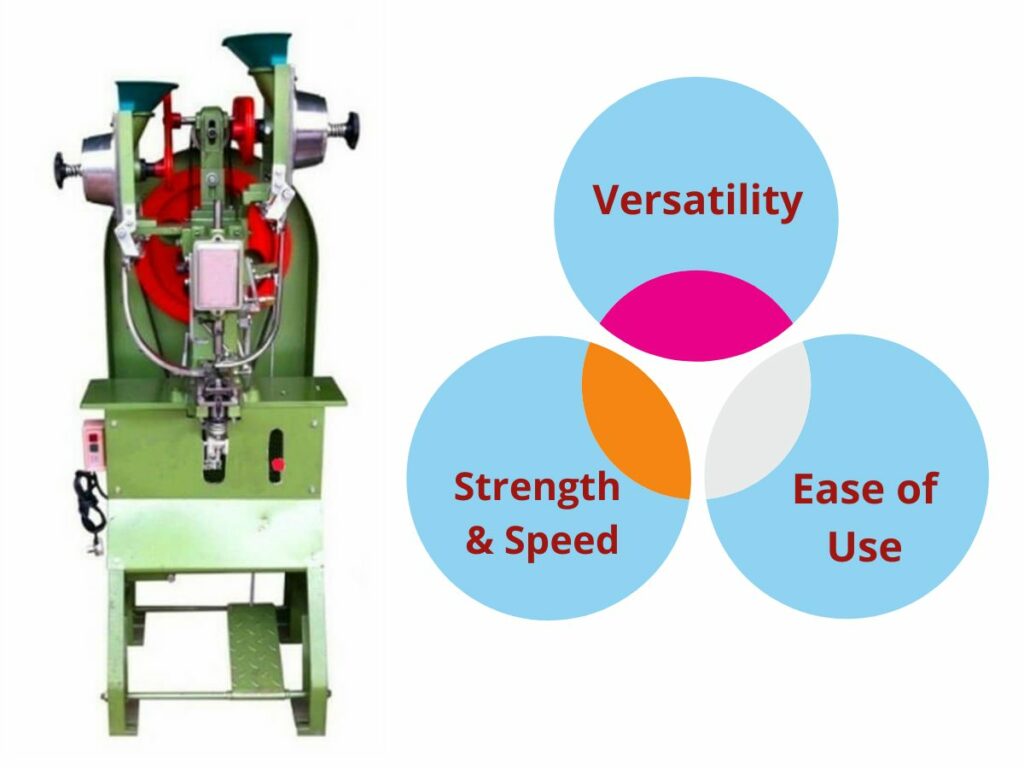

Versatility

One of the key features of the button rivet machine is its versatility. This machine can be used for a variety of applications, both industrial andDIY. It is perfect for joining thin pieces of metal together, making it an ideal option for a wide range of projects.

Strength and Speed

Another key feature of the button rivet machine is its strength and speed. The button rivet machine has a maximum loading capacity of 20 tons, making it capable of handling even the heaviest materials with ease. This button rivet machine also rotates at a speed of 60 rpm on its standard base, allowing for quick and efficient joining of materials together.

Ease of Use

The button rivet machine is also known to be very easy to use. Its simple design and controls make it easy for anyone to use, regardless of their experience level. With just a few simple steps, you can have your button rivet machine up and running, ready to join materials together quickly and easily.

Overall, button rivet machines are a great option to consider. They offer a simple and easy means of joining materials together, and they also come with a variety of key features that set them apart from other methods of joining materials.

3

Benefits of Using Button Rivet Machine

When it comes to button rivet machines, many benefits can be enjoyed. Some of these benefits include the following:

Low Costs

Button rivet machines can be purchased at a reasonable price. This is beneficial because button rivets do not have to be purchased from a button maker, who may charge an arm and a leg for button rivets.

Low Maintenance

Button rivet machines do not require a lot of maintenance. The button machine does not need oiling or cleaning very often. When it is time to oil button rivet machines, this can be done easily and quickly.

Durable

Button rivet machines are very durable and can be used to rivet buttons countless times before needing to be replaced, meaning that they will last for many years with proper care.

High Level of Precision

Button rivet machines also give buttoners and button makers a high level of precision. This is because button riveting tools like button presses and automatic button presses can be used. These button pressing tools work perfectly fine without any other adjustment needed for buttoning work that takes place in the button factory or button shop.

Safe to Use

The button rivet machine is safe to use because there is no need for apilot hole. However, it should be used with care when buttoning together any material that is under pressure or being held in place by other means.

Therefore, buttoners and button makers can benefit in many ways when using button rivet machines.

4

The Difference Between a Button Rivet Machine and Other Types of Rivet Machine

A button rivet machine is a type of rivet machine that is used for small, button-sized rivets. It is usually used for light-duty jobs, such as attaching a button to a piece of fabric. Other types of rivet machines are typically used for heavier-duty jobs, such as attaching metal plates.

Button rivet machines are typically manual machines that require multiple button presses to complete a job. Other types of rivet machines are automated, meaning they can be programmed to complete the same manufacturing process over and over again.

Some button rivet machines are handheld and battery-powered, whereas other types of rivet machines require more power. These heavier-duty machines typically need to be attached to a workbench.

Button rivets and button machine rivet tools are typically less than an inch in length and diameter and range from 1/16 to 3/8 inches wide. Other types of rivet tools and rivets are usually larger in length and diameter, ranging from 1/4 to 3 inches wide.

5

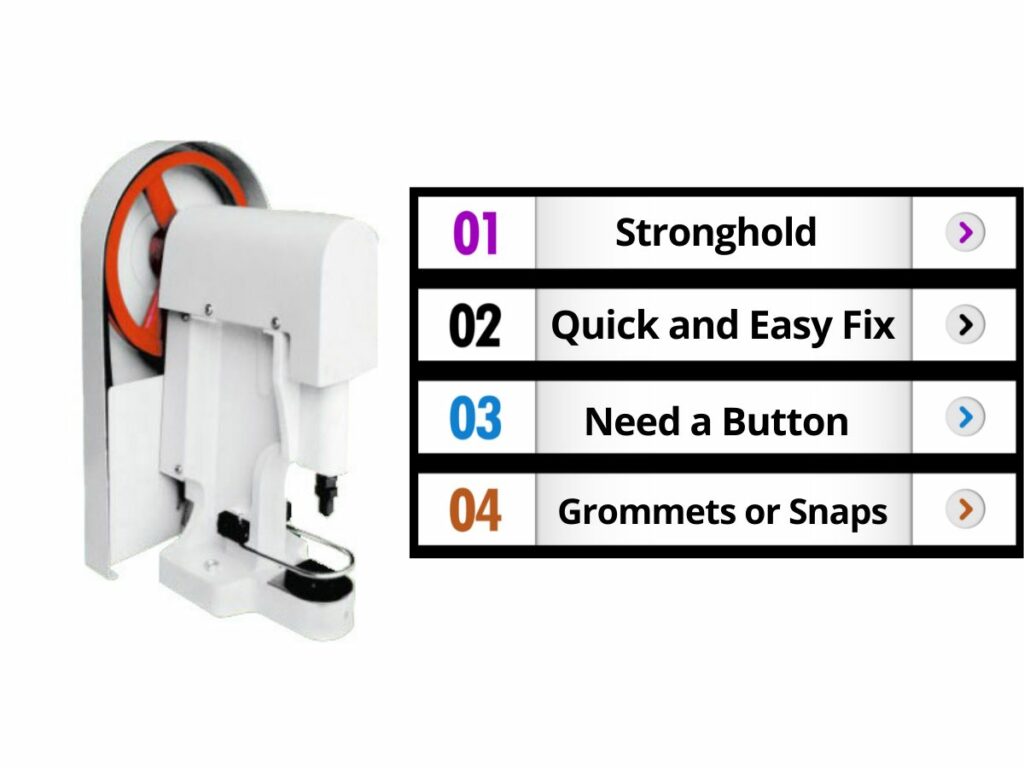

When You Should Use a Button Rivet Machine

Button rivet machines are a great way to join two pieces of material together. They are perfect for projects that need a strong and durable hold, such as making a button.

There are a few times when you might want to use a button rivet machine:

When You Need a Stronghold

Button rivet machines provide a much stronger hold than traditional staples or nails. If you need your project to be durable and withstand heavy use, then using a button rivet machine is the way to go.

When You Need a Quick and Easy Fix

If you need to quickly and easily fix a button, a button rivet machine is a way to go. It can be done in minutes and will be much more secure than using a traditional staple or nail.

When You Need a Button

Who doesn’t need a button? If you’re out of buttons or just need a button, don’t have time to head to the store and buy one, then use a button rivet machine. A rivet machine for jeans button is a great way to button your jeans if the button comes off.

When You Need Grommets or Snaps

If you need grommets or snaps, then you’ll want to use a button rivet machine. They are perfect for attaching grommets and snaps securely onto fabric. A grommet & snap press machine is a great way to keep your button from falling off.

If at least one of these situations fits your project needs then you should use a button rivet machine.

6

Step by Step Guide on Using Button Rivet Machine

A button rivet machine is a handy tool that can be used to quickly and easily attach buttons to the fabric. Here is a step by step guide on how to use one:

| No. | Steps |

|---|---|

| Step 1 | Prepare Button and Fabric |

| Step 2 | Drill Buttonholes |

| Step 3 | Position Button |

| Step 4 | Set Button and Press Down |

| Step 5 | Remove Button and Finish |

| Step 6 | Trim Buttonhole Excess Fabric |

| Step 7 | Finished Button |

Step#1 Prepare Button and Fabric

Before button riveting, the button should be properly attached to the button shank. While fabric should be prepared for button use by pressing it with an iron set to the appropriate temperature level.

Pressing is also required before sewing or attaching buttons to make sure that wrinkles are flattened out and at the same time prevent seams from puckering.

Step#2 Drill Buttonholes

The buttonhole needs to be drilled into the button fabric. Measure the buttonhole according to button size and then mark small dots at each end of its perimeter with a marking pencil.

Use button drill bits to create buttonholes that are 1mm smaller compared to button shank diameter. The buttonhole should be drilled with a button drill bit that is the same size as the button shank.

Step#3 Position Button

Position the button on top of the buttonhole. The button’s placement should be symmetrical with the buttonhole.

Step#4 Set Button and Press Down

Using a button press, firmly press down and hold the button in place while turning the knob to set the button. Keep pressure applied for about 10 seconds after one full turn of the rotary handle because button posts need to be rounded off to make sure the snug button fits.

Step#5 Remove Button and Finish

After the button is set, release the button from the button press by turning the knob in the opposite direction of rotary handle movement. This will cause the button post and rivet bottom to separate and allow the button shank to slip out the hole.

Step#6 Trim Buttonhole Excess Fabric

If there is buttonhole excess fabric, use buttonhole cutter pliers to trim away buttonhole extended material. Make sure that the button shank fits into button post holes without any problems.

Step#7 Finished Button

Your button has been successfully attached using a button rivet machine. Now you can sew buttons onto the garment and be ready to wear!

Now that you know how to use a button rivet machine, you can attach buttons quickly and easily to your button-up shirts, pants, bags, and other clothing. Follow the steps above to use one properly.

Here’s a quick video to guide you in using Button Rivet Machine:

7

Button Rivet Machine Manufacturing Process

A button rivet machine is a riveting machine used to join two pieces of metal by passing a button-shaped rivet through the pieces and then securing it with a riveting tool.

The button rivet machine manufacturing process can be divided into the following stages:

Step#1 Pre-Production

In the button rivet machine manufacturing process, pre-production is as important as other parts as it lays a foundation for the successful delivery of button rivet machines. In this stage, button rivet machines are designed and drawings with specifications are created to be used in production. Without proper planning, button rivet machines cannot be manufactured.

Step#2 Riveting

Buttons are initially shaped into the button rivet machine shape using stamping or pressing machines. To make button rivets, button dies are used to cut button blanks from the flat material sheet in the rivet press machine. After this stage, button rivets are ready to be inserted into holes in button fasteners.

Step#3 Finishing

In the button rivet machine manufacturing process, finishing is a crucial part as it gives button rivets their final shape and smoothness required for button fasteners. The button surface is finished using button grinders, button polishers, or button lappers to achieve the desired finish.

Step#4 Quality Control

Quality control is crucial in the button rivet machine manufacturing process as it ensures that button rivets are up to the quality standard. QA inspectors check button rivets for surface finish and dimensions and make sure they meet specifications.

Step#5 Packaging

After button rivets pass quality control, they are packaged using button packing machines. In the button rivet machine manufacturing process, the packaging is an important stage as it ensures safeties of the item during storage and shipping. The button rivet machine is packed in a container for shipping or storing to ensure button rivets are safe.

Step#6 Delivery

Button rivet machines are delivered through the distribution channel to join button fasteners together by button rivets so they can be used in appliances, garments, home textiles, and other products.

The button rivet machine manufacturing process is as important as other parts as it lays a foundation for the successful delivery of button rivet machines.

8

Button Rivet Machine Average Price

When it comes to button rivet machines, there are a few things you need to consider before making a purchase. One of the main factors you’ll have to think about is the price of the button rivet machine.

The button rivet machine is a device that is used to join two pieces of material together by driving a button-shaped rivet through the pieces. The average price of a button rivet machine varies depending on the features and capabilities of the machine.

Some of the factors that can affect the price include the size and power of the machine, as well as the number of buttons that the machine can produce at once. Generally, a button rivet machine will cost anywhere from $100 to $200.

If you want to save money make sure to checkout button rivet machines from several different retailers before making a purchase. Try to think about what you need the button rivet machine for before making a purchase.

This will help you narrow down your options and find a button rivet machine that is most suited to your needs.

9

Where to Find the Best Deals on Button Rivet Machine

There are several places where you can find great deals on button rivet machines. Here are just a few recommendations:

Riveth

Riveth is one of the most manufacturers in China. We have a button rivet machine R&D department to provide a high-quality button rivet machine for you at a competitive price. We deliver button rivet machines to several countries worldwide. If you have a question contact us at Riveth or visit our website at Riveth.com

Amazon

Amazon is a great place to find deals on all kinds of things, including button rivet machines and universal hand press. They often have sales going on, and you can usually find some good discounts there.

eBay

eBay is another great place to find deals on button rivet machines. It’s a popular auction site, so there are always a lot of machines up for grabs at great prices. They have good terms of service and a reliable anti-fraud system.

Therefore, there are many places where you can find button rivet machines for a good price, so it should be easy to find what you are looking for without having to pay too much.

10

Tips Before Using Button Rivet Machine

When using the button rivet machine, there are a few things you should keep in mind. Here are some tips:

- Make sure the button rivet machine is properly plugged in and turned on before use.

- Make sure the button rivet machine is placed on a stable surface before use.

- Make sure the button rivet machine is set to the correct riveting specifications for the button size you are using.

- Make sure the parts of the button rivet machine are properly aligned before you start using it.

- Make sure the workpiece is secured before you start riveting.

- Apply even pressure when riveting to ensure good results.

- Make sure the button rivet is properly inserted into the buttonhole before you start riveting.

- Make sure the button is not too thick before you start using the button rivet machine.

- Make sure you are using button rivets that are made out of the same materials before you start buttoning them together.

Overall, button rivet machines are very easy to use. You just need to make sure you are using them properly before starting buttoning projects together with button rivets.

11

Conclusion

This machine is perfect for both home and industrial use and can handle a wide range of riveting jobs.

If you need a quick way to add buttons to your garments, this riveting tool will be perfect for you. You won’t find another device like it on the market today! Whether you are looking for something industrial or home-based, the Button Rivet Machine has got everything covered. This product is great if you are looking for quality at an affordable price point too!

Click here now and purchase a Button Rivet Machine today!

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.