PRODUCT FEATURES

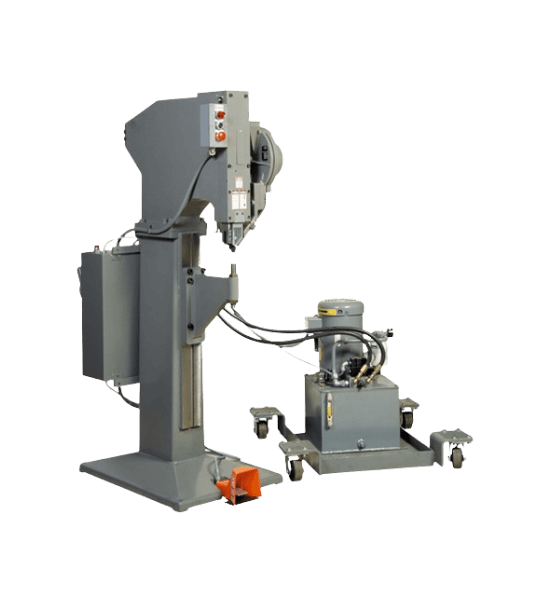

Hydraulic Rivet Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Hydraulic Rivet Machine: The Complete Guide

As a business owner, you know that it’s important to stay up-to-date on the latest machines and tools.

If you’re thinking of investing in a hydraulic rivet machine, then this guide is for you! In this post, we’ll discuss what a hydraulic rivet machine is, how it works, and tips for choosing the right model.

Plus, we’ll provide an overview of some of the top hydraulic rivet machines on the market today. So whether you’re just starting or you’re looking to upgrade your current machine, read on for all the info you need!

Table of contents

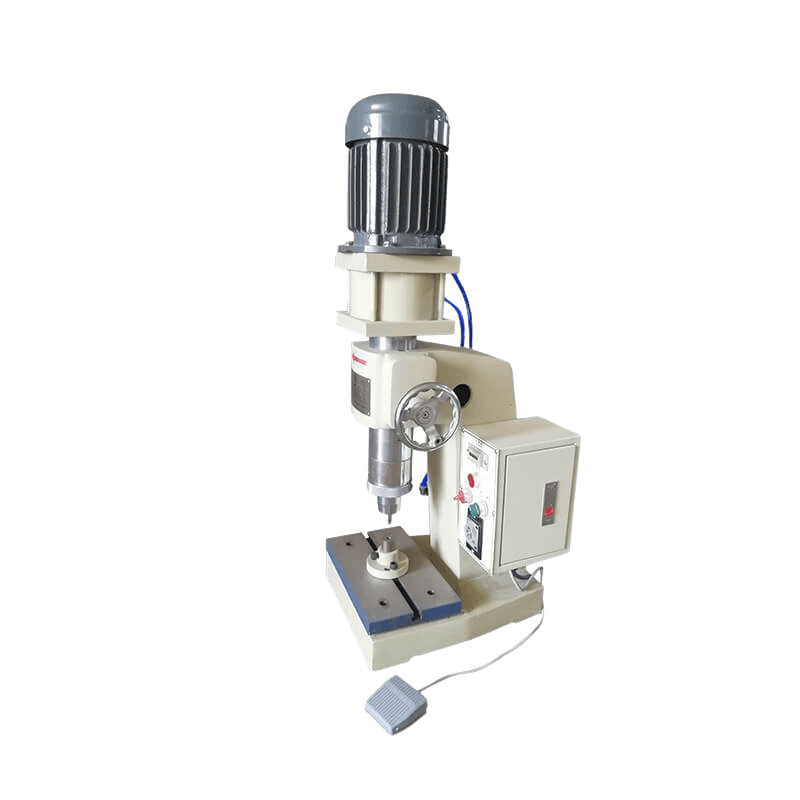

1. What Is a Hydraulic Rivet Machine

A hydraulic rivet machine is a type of riveting machine that uses hydraulic pressure to drive the rivet. This type of machine is often used in heavy-duty applications, such as construction or manufacturing.

A hydraulic rivet machine has a hydraulic pump that uses hydraulic pressure to drive the rivets. The hydraulic pump is connected to the hydraulic cylinder, which moves the rivets into place and drives them into place.

The hydraulic cylinder can be moved by either a manual or electric motor. A hydraulic riser also contains a reservoir for storing fluid, which is used to power the hydraulic pump.

2. Uses of a Hydraulic Rivet Machine

A hydraulic rivet machine is a tool that is used to join two pieces of metal together by using rivets. It can be used in a variety of applications, including construction, automotive manufacturing, and more.

A hydraulic rivet machine is a hydraulic rivet tool that uses hydraulic pressure to drive the rivets into the metal.

This makes it a more powerful tool than traditional hand-operated rivet guns.

It can also be used for larger rivets, which can be difficult to use with a hand-operated gun.

3. How To Choose the Right Hydraulic Rivet Machine for Your Needs

When looking for a hydraulic riveting machine price, it is important to deliver the needs of the project at hand.

Some things to consider include the type and size of rivets to be used, the cycle time, the thickness of the materials to be joined, and the required force.

Some factors to consider when choosing a hydraulic rivet press machine include:

Type and Size of Rivets to be Used

Hydraulic riveters come in a variety of sizes, and it is important to choose the right size for your application depending on your settings.

It is also important to consider whether you will be using hydraulic rivet guns or hydraulic pop rivets, as these two methods differ greatly in terms of force required.

The Thickness of the Materials Being Joined

Hydraulic rivet machines can be used on a variety of different materials, but it is important to choose a machine that is capable of providing the required force for your project.

Required Force

Hydraulic rivet machines come with different levels of force, so it is important to select one that can provide the necessary amount of pressure for your project.

There are a variety of hydraulic rivet machines available on the market, so it is important to do some research before making a purchase.

It is also important to have a clear idea of what you want the machine to do, to ensure that you select the right one.

Once you have considered these factors, you will be able to find hydraulic rivet machines that are suitable for your needs.

4. Different Types of Hydraulic Rivet Machine

There are many types of hydraulic rivet machines on the market, with each one having its advantages and disadvantages. Some of the more common types include the following:

Hand Hydraulic Rivet Machine

This is a small, portable machine that is operated by hand. It is ideal for use in tight spaces or when working with delicate materials.

Pneumatic Hydraulic Rivet Machine

This type of machine uses compressed air to power the hydraulic system. It is typically more powerful than other types of hydraulic rivet machines and can be used for high-volume production.

Electric Hydraulic Rivet Machine

This type of machine is powered by electricity and is the most common type of hydraulic rivet machine. It is reliable and efficient, but it requires a lot of upkeep and maintenance.

5. How To Use a Hydraulic Rivet Machine Safely and Effectively

A hydraulic rivet machine is a powerful tool that can be used to fasten or join materials together.

It is important to use this tool safely and effectively to avoid accidents and ensure the quality of the work.

Here are some tips on how to do this:

- Always read the safety instructions before using the hydraulic rivet machine.

- Make sure the hydraulic rivet machine is properly calibrated before use.

- Keep your hands and fingers clear of the moving parts of the machine.

- Use caution when working with metal sheeting, as it can be sharp.

- Make sure the work area is clean and free of obstructions before starting work.

- Use the correct size rivets for the job.

- Keep the hydraulic rivet machine clean and lubricated.

- Store the hydraulic rivet machine in a safe place when not in use.

By following these tips, you can safely and effectively use a hydraulic rivet machine to get the job done.

Here is a quick video on how to use a Hydraulic Rivet Machine.

6. 7 Tips for Maintaining Your Hydraulic Rivet Machine

Maintaining your hydraulic rivet machine is essential for ensuring its longevity and optimal performance. Here are a few tips for keeping your hydraulic rivet machine in good condition:

| No. | Tips |

|---|---|

| 1 | Keep the Machine Well-Lubricated |

| 2 | Clean the Machine Regularly |

| 3 | Check the Machine for Wear and Tear |

| 4 | Keep the Hydraulic Fluid Clean and Levelled |

| 5 | Tighten Hoses and Fittings |

| 6 | Avoid Any Sharp Edges |

| 7 | Drain Hydraulic Fluid from Unused Machine |

#1 Keep the Machine Well-Lubricated

Make sure the hydraulic rivet machine is properly lubricated. Lubricating the machine will help keep it running smoothly.

#2 Clean the Machine Regularly

Keep the hydraulic rivet machine clean. Dirty machines can cause problems and may not work correctly.

Always keep the hydraulic rivet machine in a clean, dry environment when it is not being used.

Dirt and moisture can get into hydraulic fittings, hoses, and equipment could lead to hydraulic fluid contamination.

#3 Check the Machine for Wear and Tear

Regularly check the hydraulic rivet machine for any damage or wear and tear. Damaged machines may not be safe to use.

Inspect the rivet gun and dies for wear and tear regularly. Damaged equipment can result in improper riveting and potential safety hazards.

#4 Keep the Hydraulic Fluid Clean and Levelled

Always keep the hydraulic fluid clean and at the proper level. Dirty hydraulic fluid can cause damage to the equipment.

#5 Tighten Hoses and Fittings

Make sure all hydraulic hoses and fittings are tight and secure. Loose hoses can cause hydraulic fluid to leak, which can lead to damage.

#6 Avoid Any Sharp Edges

Make sure hydraulic lines are not rubbing up against any sharp edges. This can cause hydraulic lines to rupture and hydraulic fluid to leak out.

#7 Drain Hydraulic Fluid from Unused Machine

If hydraulic equipment is not being used for an extended period, the hydraulic fluid should be drained from the system and replaced with fresh hydraulic fluid.

This will prevent contaminants from accumulating in the system over time which could lead to problems down the road when it comes to using again.

7. Benefits of Using a Hydraulic Rivet Machine

There are a few key benefits to using a hydraulic rivet machine over other types of riveting machines. Advantages of hydraulic rivet machines include the following:

Heavy-duty Applications

Hydraulic rivets are much stronger than traditional or pneumatic rivets, making them a better option for heavier-duty applications.

Versatility

Additionally, hydraulic riveting machines are much more versatile than other types of riveters; they can be used for both light and heavy-duty riveting jobs and can handle a wide range of rivet sizes.

Easy-to-Use

Hydraulic rivet machines are typically easier to operate than other types of riveters, making them ideal for inexperienced and novice users.

Speedy

Hydraulic rivet machines are incredibly fast, which means you can get the job done quickly.

Durability

They are also very durable and reliable, meaning they can withstand even the most strenuous jobs.

Accuracy and Efficiency

And finally, hydraulic rivet machines are extremely accurate and efficient, ensuring that you get the most out of your machine.

If you’re looking for a quality hydraulic rivet machine, we recommend checking out hydraulic rivet machines from Riveth.

8. 5 Troubleshooting Tips for Common Problems With Hydraulic Rivet Machines

There are a few common problems that can occur with hydraulic rivet machines, and troubleshooting them can be tricky. Here are a few tips to help you out:

#1 Check the Hydraulic Fluid Level

Make sure that the hydraulic fluid is at the correct level. If it is too low, the machine will not be able to function properly.

#2 Check for Air Pockets in the Rivet Machine

If the hydraulic rivet machine is not functioning correctly, check to see if there is air in the hydraulic system. This can often be corrected by bleeding the system.

#3 See if Anything is Obstructing the Machine

If the hydraulic rivet machine is not heating up properly, there may be something blocking the flow of heat to the rivets. Check to see if anything is obstructing the heaters or the vents.

#4 Use the Correct Hydraulic Fluid

Make sure that you’re using the right hydraulic fluid for your machine. An incorrect hydraulic fluid might irreparably damage machine parts.

#5 Clean the Hydraulic Valves with Solvent

Also, check the hoses and fittings to make sure they’re all properly connected. If the machine is still not functioning correctly, try cleaning the hydraulic unit and the valves with a solvent.

If the problem persists, you may need to replace the hydraulic seals or the hydraulic pump.

These are just a few of the common problems that can occur with hydraulic rivet machines. If you are having trouble with your machine, be sure to consult the manual or contact the manufacturer for help.

They will be able to troubleshoot the problem and help you get your machine up and running again.

9. Conclusion

We’ve discussed what a hydraulic rivet machine is, how it works, and tips for choosing the right model. Plus, we’ve provided an overview of some of the top hydraulic rivet machines on the market today.

Contact us at Riveth if you have any questions about which machine would be best for your business. We’d be happy to help!

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.