PRODUCT FEATURES

Radial Riveting Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us at [email protected]

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

BUYER’S GUIDE

Radial Riveting Machine

Radial Riveting Machine is one of the best tools for the Radial Riveting process. It is used to fix radial rivets in different industries like automotive, construction, and many more. it has high quality and provides a good service to customers all around the world.

This is a riveting machine that can be used to install, repair, and maintain various kinds of industrial machinery. It is ideal for use by professional mechanics who work on heavy machinery such as tractors, cranes, and excavators.

A radial Riveting Machine is a fast, efficient, and accurate solution to your riveting needs. Whether you are looking for a manual or electric model, Radial Riveting Machine has the right tool for the job.

Table of contents

1. Radial Riveting Machine Definition

A radial riveting machine is a type of riveting machine that uses a rotating die to produce rivets in a radial pattern. This type of machine is often used in the automotive and aerospace industries.

A radial riveting machine is a type of riveting machine that uses radial force to join two pieces of metal together. This radial force is typically created with a press or hydraulic cylinder.

Supplied rivets are then inserted into one of two pieces that are to be riveted together. The rivet is then positioned between the pieces and placed under radial pressure from the orbital riveter machine.

Radial forming riveting machines can be manual or automatic. Manual radial riveting machines require less investment, but they are more time-consuming and may not provide as much production speed as an automatic machine.

2. Benefits of Using a Radial Riveting Machine

The radial riveting machine offers many benefits over traditional methods of joining two pieces of material together, including speed, accuracy, and versatility.

Some notable benefits are listed below:

Increased Production Speed

The radial riveting machine offers increased production speed due to its continuous operation. The radial riveting machine can be programmed to perform radial riveting on repeat without the need for continual monitoring, allowing other tasks to take place simultaneously.

Reduced Manufacturing Time

A radial riveting machine can drastically reduce the manufacturing time for products that require riveting. This is because a radial riveting machine can complete the orbital riveting process much faster than a human could. Additionally, standard riveting machines are often automated, so they can work quickly and accurately without any mistakes.

Great Versatility

Radial riveting machines are available in all shapes and sizes, so they can be used to perform radial riveting on a wide range of products. Also, ra radial riveting machines are designed with many standard parts that can be changed out or replaced as needed.

Improved Quality and Consistency of Rivets

Radial riveting machines produce high-quality, consistent rivets that meet all manufacturing specifications. Additionally, radial riveting machines can produce a greater number of rivets in a shorter amount of time, which leads to increased energy efficiency and decreased production costs.

These radial riveting machines are designed to handle different workpieces of all shapes and sizes, which is beneficial for ensuring that no piece goes to waste.

3. Types of Materials Can Be Riveted With a Radial Riveting Machine

There are many types of materials that can be riveted with a radial riveting machine. Some of the most common materials are:

Steel

Steel is a common material that can be riveted with a radial riveting machine. It is the most cost-effective option because it doesn’t require any extra accessories to rivet steel. Steel can also be riveted quickly and efficiently with a radial riveting machine.

Aluminum

Aluminum sheets must be anodized before radial riveting. This will make the aluminum stronger and more resistant tocorrosion. If aluminum sheets do not have this process done, they can split in extreme weather conditions because of differences in expansion rates.

Brass

Brass is another common material that can be used with radial riveting machines. However, the brass should only be riveted with radial riveting machines if it is annealed. Annealing brass will make it more ductile which leads to better radial riveting results.

Titanium

Titanium is another material that can be used with radial riveting machines. It is important to note that titanium has a low shear strength; therefore, it should not be riveted with radial riveting machines. This material can be successfully riveted by other methods such as impact riveting or blind riveting.

Therefore, radial riveting machines are great for radial riveting many types of materials. If you need to rivet any of the above materials, radial riveting is an effective option.

4. Different Types of Radial Riveting Machines

Radial riveting machines come in different types, each with its advantages and disadvantages.

There are two main types of radial riveting machines:

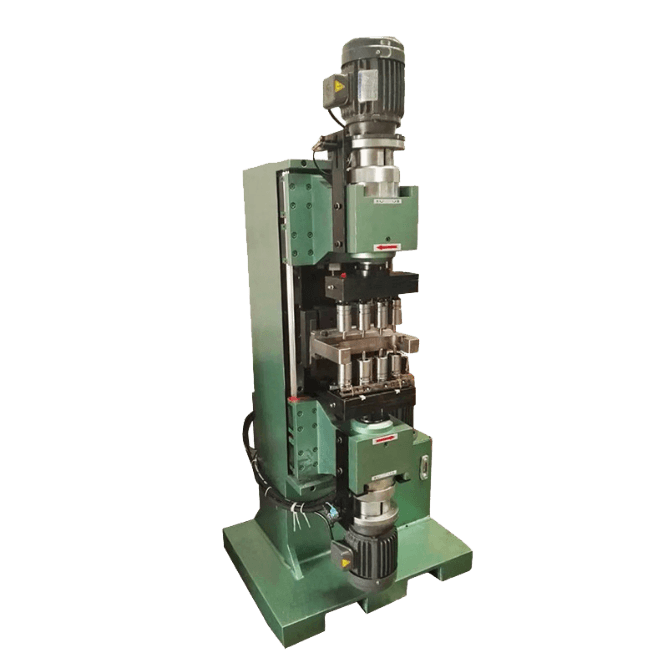

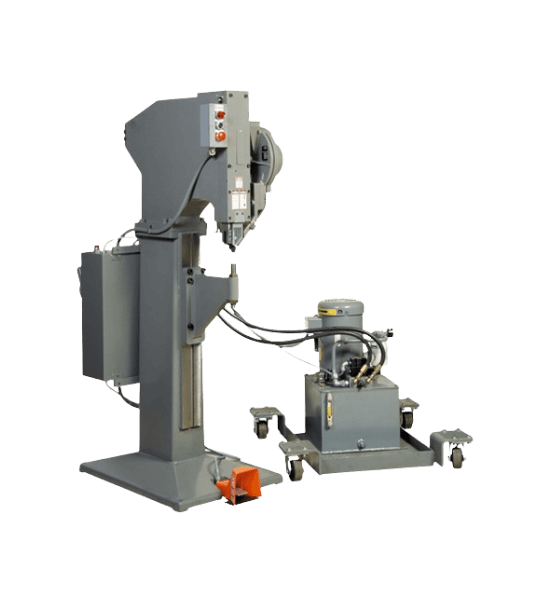

Vertical Style Machines

Vertical style radial riveting machines are the most popular type. They are mostly used in production environments because they are fast and highly efficient machines. However, they can be quite large and require a lot of space.

Horizontal Style Machines

Horizontal radial riveting machines are smaller than vertical radial riveting machines. They aren’t as fast and efficient but they take up less space. They are mostly used in smaller production factories where speed isn’t an issue.

Thus, radial riveting machines come in different types depending on the delivered remarkable progress.

5. Common Radial Riveting Machine Applications

Radial riveting machines are versatile tools that can be used for a variety of tasks. Some of the most common radial riveting machine applications include:

Joining Metal Parts

Radial riveting machines can be used to join metal parts together by riveting them in place. This is a common technique for attaching metal panels, and radial riveting machines are the best tool for the job.

Securing Fasteners

Radial riveting machines can also be used to secure fasteners in place. This is often done on assemblies that require repeated disassembly and reassembly, such as in the automotive or aerospace industries.

Repairing Damaged Parts

In some cases, radial riveting machines are used to repair damaged parts. This process involves removing the damaged part, drilling radial holes in the new piece, and inserting rivets into them. The radial riveting machine is then used to install the fasteners between the two pieces of metal.

Creating Fluid-tight Seals

Radial riveting machines are commonly used in the construction of fluid-tight seals, such as with fuel tanks. In this case, radial holes are drilled into the tank to allow for welding or other sealing processes. Bracker radial riveting machine can then be used to install fasteners between the pieces of metal that were just welded together.

Securing Porous Materials

Radial riveting machines can also be used to secure porous materials, such as concrete. In this case, radial holes are drilled into the product and radial rivets are installed between them.

Overall, radial riveting machines can be used for a variety of purposes. For these reasons, radial riveting machines continue to grow in popularity, which means radial riveters must prove their worth by completing jobs with accuracy and efficiency.

6. Workpieces That Can Be Produced With a Radial Riveting Machine

A radial riveting machine is a type of riveting machine that uses radial force to secure workpieces. This type of machine is commonly used in the automotive and aerospace industries.

Some of the workpieces that can be produced with a radial riveting machine include:

Automotive Body Panels

Automotive body panels are typically made from sheet metal that is bent and shaped to form the desired panel. The panels are then riveted or bolted to the car’s frame. Radial riveting machines are ideal for securing automotive body panels because they provide radial force, which ensures a secure connection.

Aircraft Fuselages

Aircraft fuselages are another type of workpiece that can be produced with a radial riveting machine. Aircraft fuselages are typically made from aluminum or titanium alloys. They are highly-structured components that require a high degree of precision.

Radial riveting machines are ideal for manufacturing aircraft fuselages because they provide radial force, which ensures a secure connection. They also produce minimal distortion, which is important for maintaining the structural integrity of the fuselage.

Spacecraft Components

In the aerospace industry, radial riveting machines are used to secure a variety of spacecraft components. These include panels, fairings, and nacelles. Spacecraft components require a high degree of precision because they must function properly in some of the most extreme conditions on Earth or in space.

A radial riveting machine is a versatile tool that can be used to secure a variety of workpieces. It is important to note that this type of machine requires a high degree of accuracy and precision.

7. Some Disadvantages of Using a Radial Riveting Machine

A radial riveting machine can be a great asset in a workshop, but like any riveting tool, it has its disadvantages. Here are some of the main ones:

They Can Be Expensive

Radial riveting machines can be expensive, so they may not be affordable for everyone.

They Require a Certain Level of Skill To Use Effectively

Radial riveting machines can be difficult to use for people who don’t have a lot of experience with them. They require a certain level of skill to use effectively, and if you’re not familiar with the machine, you could end up causing damage to the parts you’re trying to rivet together.

They Can Be Slow To Use

Radial riveting machines aren’t the quickest riveting tools you can use, so if efficiency is important to you, a radial riveting machine may not be ideal.

Overall, radial riveting machines are a great asset to have in a workshop, but they also have some disadvantages you should be aware of.

8. Radial Riveting Machine Maintenance

Regular maintenance is essential for ensuring the proper operation of a radial riveting machine. Here are some tips for maintaining your radial riveting machine:

- Always keep the radial riveting machine clean and free of debris.

- Make sure all screws and bolts are properly tightened.

- Check the radial arm for any signs of wear or damage.

- Make sure all radial riveting machine controls are working properly.

- Inspect radial riveting machine pneumatic components for leaks.

- If radial riveting machine components are broken or damaged, replace them.

- When the radial riveting machine is not in use, drain the airlines and lower radial arm to prevent damage.

- An automatic lubrication system can be installed to reduce radial riveting machine maintenance and downtime.

If you follow these tips, you can keep your radial riveting machine in excellent condition for a long time. If any of the radial arm rollers should need replacing, contact a local supplier to see what part is needed and complete the requested maintenance.

9. Radial Riveting Machine Cost

The cost of a radial riveting machine can vary depending on the features, and capabilities that are desired. Generally, however, a radial riveting machine will cost between $1,000 and $5,000. Other optional accessories such as dies and mandrels can also add to the cost of the machine.

A radial riveting machine is a specialized tool used in industrial applications to join two pieces of metal together. The radial riveting machine uses a radial arm to hold the rivet in place while it is being hammered into the metal.

The radial riveting machine is a more expensive option than other types of riveting machines, but it offers a higher level of accuracy and can be used to join a wider range of materials.

For more information, contact companies like Riveth that offer different radial riveting machine models that may be a good fit for your workshop.

10. 7 Tips Before Buying Radial Riveting Machine

When looking to buy a radial riveting machine, there are a few things you should keep in mind. Here are 10 tips to help you make the best purchase:

| No. | Tips |

|---|---|

| 1 | Consider the Size of the Machine |

| 2 | Think About Ease of Use |

| 3 | Think About the Quality of the Machine |

| 4 | Think About Capacity |

| 5 | Think About User Reviews |

| 6 | Check for Warranty Policy |

| 7 | Compare Prices |

#1 Consider the Size of the Machine

When looking to buy a radial riveting machine, be sure to consider the size of the machine. You want to make sure that it will be able to fit comfortably in your workshop.

#2 Think About Ease of Use

Before buying a radial riveting machine, it is important to think about ease of use. The more complicated the radial riveting machine, the more likely you are to have issues with using it regularly. Think about how long it will take you to master this radial riveting machine before purchasing it.

#3 Think About the Quality of the Machine

Before buying a radial riveting machine, it’s important to consider the quality of the radial riveting machine. A high-quality radial riveting machine will often come with a higher price tag, but it will be more durable and reliable while also providing a better user experience.

#4 Think About Capacity

Before you buy a radial riveting machine, think about capacity. Consider what you will be using the radial riveting machine for and how many parts you would like to produce daily. By keeping this in mind, you can find a radial riveting machine that meets your needs.

#5 Think About User Reviews

Before purchasing a radial riveting machine, think about user reviews. By reading through previous customer experience with the radial riveting machine, you can gain a better idea as to what the radial riveting machine is like and whether or not it will be worth purchasing.

#6 Check for Warranty Policy

Before buying a radial riveting machine, you should check for its warranty policy. A radial riveting machine with warranty coverage provides users with more peace of mind when they are using it. This radial riveting machine warranty will also protect the radial riveting machine against various issues in case they should occur.

#7 Compare Prices

When looking to buy a radial riveting machine, it’s important to compare prices. You want to find the best deal on a radial riveting machine that meets your needs. By comparing prices, you can find the radial riveting machine that is right for you.

Overall, radial riveting machines provide users with a way to create great items that they can sell and take pride in. By considering the tips mentioned above, you will be able to find the radial riveting machine that is perfect for your needs.

Here’s a video on how to use Radial Riveting Machine.

11. Conclusion

Radial riveting machines are some of the best tools for the radial riveting process. They are used in a variety of industries to fix radial rivets.

A radial Riveting Machine is a fast, efficient, and accurate solution to your riveting needs. Whether you’re working on heavy machinery or just need something that will help with your home improvement projects – this tool can do it all! You won’t find another product out there that does what this one does at such an affordable price point.

Click here right now to purchase one today!

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.