PRODUCT FEATURES

Leather Rivet Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

The Rivet Machine for Leather: Everything You Need to Know

In the leatherworking world, there are a few machine staple tools that are absolutely necessary for any serious craftsman.

Probably the most important of these is the Rivet machine. This tool is used to fasten pieces of leather together by driving rivets through the material.

In this blog post, we’ll walk you through everything you need to know before making your purchase. We’ll also cover the different types of rivet machines available and provide some tips on how to choose the right one for your needs. Stay tuned!

Table of contents

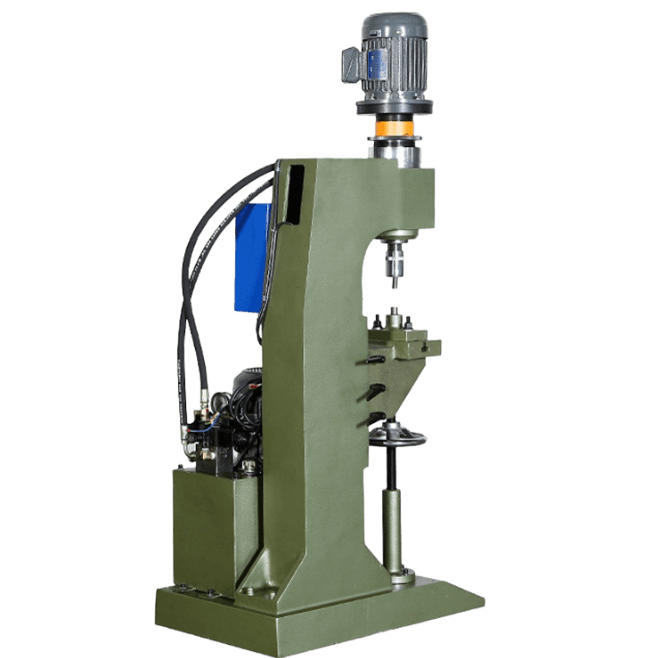

1. Rivet Machine for Leather Definition and How It Works

A rivet machine for leather is a device used to attach rivets to pieces of leather. It works by using a rivet die to create a hole in the leather, then the rivet is inserted into the hole.

The rivet setting tools then uses a rivet press to tighten the rivet against the leather, securing it in place.

2. The Different Types of Rivets Machines for Leather

A rivet machine for leather is a device that uses rivets to fasten two pieces of firmly attached material together.

Rivets are typically used in fully assembled leatherwork, where double cap rivets are inserted through a hole in one piece of material, and then setting snaps are placed on the other side to hold the rivet in place.

There are different types of rivets machines for leather, each with its benefits and drawbacks.

Some of the most common types of rivets machines for leather include the pneumatic rivet gun, the manual rivet gun, and the rivet hammer.

Pneumatic Rivet Gun

The pneumatic rivet gun is powered by compressed air and is one of the most popular types of rivets machines for leather.

This rivet gun is used to rivet leather that has been glued together. It uses air pressure to push the rapid rivets through, which makes it very fast and easy to use.

The pneumatic rivet gun has been widely used in many industries for decades because it allows workers to perform their job quickly and easily.

Many riveting machines have been used by people in the aviation industry, but rivet guns are also popular among hobbyists and crafters as well.

The rivet gun is a very versatile tool, which can be used on any kind of material that requires rivets to hold it together.

Manual Rivet Gun

The manual riveting machine is another popular riveting machine, but it requires a lot of skill to operate.

Most rivet guns require some sort of training before they can be used safely, and the rivet hammer is even harder to use because there are so many different types of rivets available.

However, the manual riveter can be used on most materials that require riveting.

Rivet Hammer

The rivet hammer is another common type of rivets machines for leather. It can be used in two ways: either as a manual riveting machine or as a rivet hammer.

A riveting machine is used to rivet leather that is not glued together, while the rivet hammer can be used on all kinds of materials including wood and metal.

3. The Benefits of Using a Rivet Machine for Leather

There are many advantages of using a rivet machine for leather. Here are some of those:

Time-saving

One of the biggest benefits is that it helps to save time. When you use a rivet machine, you can quickly and easily attach rivets to leather pieces. This makes it a fast and efficient way to work with leather.

Stronger Bonds

Another advantage of using a rivet machine is that it helps to create a strong bond between the rivets and the leather. This means that the rivets will be less likely to come loose over time.

This makes the rivet machine a great choice for projects that need to be durable and long-lasting. The rivet machine can also be used on a variety of different types of leather, including suede and full-grain.

Efficient

A rivet machine is an efficient way to attach rivets to leather because it helps reduce the amount of time that you spend working with rivets. It takes less effort to use this tool than it does if you were to use rivets by hand.

Ease-of-use

This machine makes it easier for you to create a variety of designs on leather pieces. You can choose from many different rivet sizes and shapes, which means that there are plenty of design options available for your project. It’s also easy to change out rivets so that you can add new ones.

If you have further questions as to how to install rivets in leather and how to set a rivet in leather can help you or your business, feel free to contact us at Riveth.

4. Manufacturing Process of a Rivet Machine for Leather

A rivet machine is a handy tool that can be used for a variety of applications, such as riveting leather. The following is a step-by-step guide on how to manufacture a rivet machine for Leather:

Step#1 Choosing the Appropriate Materials

Begin by choosing the materials that you will need for the project. In this case, you will need a rivet machine, a piece of leather, and some rivets.

Step#2 Matching the Rivet Size to the Leather

If you are riveting leather, you will need to choose the appropriate size rivet for the thickness of the leather. A good rule of thumb is to use a rivet that is twice the thickness of the leather.

You will also need to choose the rivet hole size. The rivet hole size should be slightly smaller than the rivet itself.

Step#3 Cutting the Leather

The rivet machine process begins by cutting the leather to the desired size and then punching holes in it using a die.

Step#4 Inserting the Rivets

The rivets are then inserted into the holes, and the rivet machine is used to close the rivets and form a tight bond. This process is often used to attach handles or straps to leather goods.

Rivet machines are also used in the manufacture of shoes, where they are used to attach the soles to the uppers.

5. Where to Find the Best Deals on Rivet Machines for Leather

Rivet machines can be found at a variety of manufacturers, online and offline stores. However, the best deals are often found online. Here are a few places to start your search:

Each of these manufacturers and stores offers a variety of rivet machines at different prices. Be sure to compare the features and prices before making your purchase.

You may also want to read online reviews to get an idea of what others think about the hand press for leather machine you’re considering.

Ultimately, the best rivet machine for leather is the one that meets your needs and fits within your budget. Do your research, compare prices, and make the best decision for you.

If you want to know more about how to attach rivets to leather and how to rivet leather, feel free to contact us at Riveth.

6. Rivet Machines for Leather Average Price

The rivet machines for leather average price is around US$1,000.

You can find rivet machines for leather that are priced at US$500. These rivet machines may be second hand or they can also be brand new.

But there is a limit to their capabilities when it comes to riveting large amounts of rivets in one go because the riveter has a smaller capacity and its punching power is limited as well.

If you are riveting a lot of rivets, then you might want to consider a more expensive rivet machine for leather that is priced at around US$2000 or more.

This rivet machine will have a higher capacity and it will also be able to punch through tougher materials with ease.

7. 10 Tips for Getting the Most Out of Rivet Machine for Leather

There are a few tips that you can follow to get the most out of your rivet machine for leather. Here are a few of them:

| No. | Tips |

|---|---|

| 1 | Use Proper Rivets |

| 2 | Place Rivets in the Correct Spot |

| 3 | Align the Rivets |

| 4 | Always Rivet in a Straight Line |

| 5 | Have Pliers on Hand |

| 6 | Lubricate and Clean the Riveter |

| 7 | Always Read the Instructions |

| 8 | Rivet from Top to Bottom |

| 9 | Apply Even Pressure |

| 10 | Rivets Should not Go Through Fabric or Plastic |

#1 Use Proper Rivets

Make sure that you use the correct rivets for the project that you are working on. Using the wrong rivets can damage your rivet machine and/or your project.

#2 Place Rivets in the Correct Spot

Make sure that you place the rivets in the correct spot. If you misplace the rivets, it can cause problems with your rivet machine and/or your project.

#3 Align the Rivets

Make sure that the rivet is properly aligned before you start riveting. This will help to ensure that your rivets are consistent and look good. Making sure the rivets and rivet holes are evenly aligned before riveting will help ensure a stronger hold.

#4 Always Rivet in a Straight Line

Make sure that you rivet the rivets in a straight line. This will allow for the easier removal of rivets and make your project look more professional.

#5 Have Pliers on Hand

Use riveting pliers to help with getting consistent riveted joints on your projects. Riveting pliers are an essential tool when you are using rivet machines because they help to ensure that the rivets are properly aligned.

#6 Lubricate and Clean the Riveter

Make sure that you keep your rivet machine clean and lubricated. This will help to ensure that your rivet machine runs smoothly and does not cause any damage.

#7 Always Read the Instructions

Always read the instructions for your rivet machine before using it. This will help to ensure that you are using the rivet machine correctly.

#8 Rivet from Top to Bottom

Make sure that you rivet all rivets on your project from top to bottom. This will help to ensure consistent riveting and make your projects look more professional.

#9 Apply Even Pressure

Apply even pressure when riveting to ensure a good seal and avoid breaking the rivet. If the rivet is too tight or too loose, it can be difficult to get it to stay in place. Adjusting the rivet size can help fix this issue.

#10 Rivets Should not Go Through Fabric or Plastic

The rivets can be used on both sides of the leather, but should not go through any other material such as fabric or plastic. Rivets can also be used to attach straps, belts, and other pieces of leather.

By following these tips, you can get the most out of your rivet machine for leather projects!

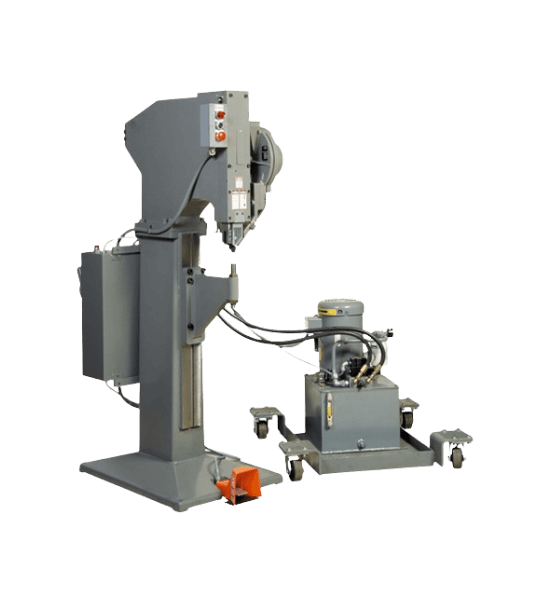

8. 5 Things to Look for When Purchasing a Rivet Machine for Leather

When purchasing a rivet machine for leather, there are several things to look for:

#1 Should accomodate the Dimensions of the Leather

The rivet machine should be able to accommodate the width and thickness of the leather you will be using.

#2 Depth Should Be Adjustable

The rivet machine should have an adjustable rivet depth so that you can customize the rivet placement. The rivet machine should have an adjustable rivet pitch so that you can change the distance between rivets.

#3 Even Pressure Distribution

The rivet machine should be able to apply pressure evenly to the rivet so that it is securely fastened.

#4 Stable Base

The rivet machine should have a stable base so that it does not move around while you are working.

#5 Easy to Operate

The rivet machine should be easy to use and operate.

When choosing a rivet machine for leather, these are the factors you should consider to make sure you find the best one for your needs.

You might want to check this video on How to Rivet Leather for Binding.

9. Conclusion

If you’re looking for a way to add rivets, eyelets, and grommets to your leather projects, the rivet machine is the perfect tool for the job. This handy little gadget can do it all, and it’s easy to use.

Contact us today at Riveth to learn more about the rivet machine and how it can help you take your leatherworking skills to the next level!

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.