PRODUCT FEATURES

Spin Riveting Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is riveth.com

Riveth.com have seen that today there are also many rivet machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and riveth.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

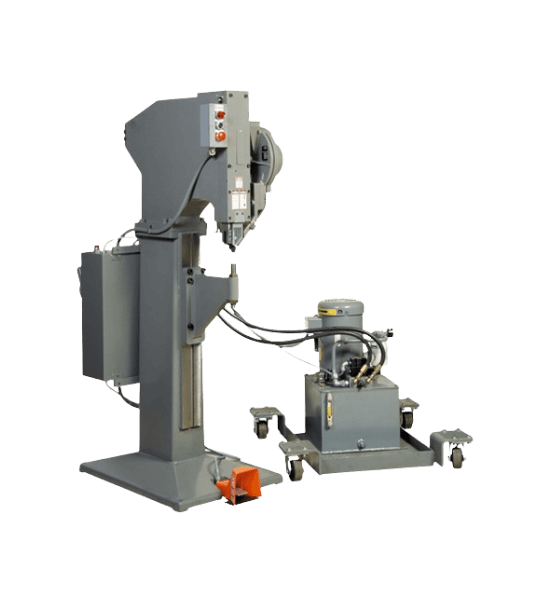

Spin Riveting Machine

The spin riveting machine is a powerful and versatile tool that can be used for a variety of purposes. It is efficient and can get the job done quickly. This model has a fast cycle time, which means you can complete your work more quickly than other models on the market.

The machine uses an electric motor to turn the chuck at high speeds, which allows it to drive in screws or rivets with ease. It features an ergonomic handle that makes it easy to hold onto while you’re working so you don’t need to worry about dropping it when you’re up on a ladder or working at an awkward angle.

The spin riveting machine also features two speeds that you can choose from to adapt it to the material you are working with. This allows you to get the best performance possible for your needs.

Table of contents

1. Spin Riveting Machine Definition and What Does It Do

A spin riveting machine is a type of riveting machine that uses a spin action to join two pieces of material together. The spin riveting machine uses a mandrel that is inserted into the rivet hole.

The mandrel is then rotated to create friction between the mandrel and the rivet. This creates heat that causes the rivet to expand and be inserted into the hole. The spin riveting machine uses the spin action to spin the mandrel which in turn rotates both pieces of material together.

The spin riveting or orbital riveting machine is designed to operate quickly by rotating the mandrel at a high speed.

2. Spin Riveting Machine Key Features

A spin riveting machine is a type of riveting machine that uses a rotating spindle to produce the rivet. This type of machine is often used in mass production settings than manual feed riveting machines because it can quickly and efficiently produce rivets. Some of the key features of a spin riveting machine include:

Ease of Use

The spin riveting machine is easy to use, making it an ideal choice for manufacturers who need to quickly produce rivets.

Speed

The orbital spin riveting machine can produce rivets quickly, making it an efficient choice for larger-scale production.

Accuracy

Spin or orbital riveting machines produce accurate rivets, ensuring a high level of quality in the finished product.

Versatility

The spin riveting machine is a spinning forming tool designed to spin cylindrical objects. This means that it can be used to spin things like washers, rods, and pipes. It can also spin tube-shaped objects with diameters of up to 20 inches.

If you want to purchase the spin riveting machine, please visit http://www.riveth.com/. The spin riveting machine is sold at Riveth at an affordable price and ships worldwide.

3. Benefits of Using Spin Riveting Machine

The spin riveting machine has many benefits that include:

Increased Production

The spin riveting machine can produce more rivets in a shorter time than manual riveting. This means that you can produce more products in a shorter time, which leads to increased profits.

Increased Efficiency

The spin riveting machine is very efficient and can be used for a variety of tasks. This means that you can save time and money by using one machine for multiple tasks.

Increased Quality

The spin riveting machine or orbital rivet machine produces high-quality rivets that are strong and durable. This means that your products will be of the highest quality and will last longer.

Wider Application

The spin riveting machine can be applied to many areas such as the automotive, hardware, and packaging industries. This means that it is versatile and you can use it anywhere.

Easy to Use

The spin riveting machine is simple and easy to operate which makes it valuable for people without training in machines, such as apprentices or students learning on the job.

Increased Safety

The spin riveting machine is safe to use and comes with an interlock switch that prevents children from tampering with it while adults are away. This means your company will abide by all of the safety regulations set out by OSHA, which can increase profits due to fines associated with safety infractions.

4. The Difference Between a Spin Riveting Machine and Other Types of Riveting Machine

There are different types of riveting machines available on the market. The spin riveting machine is a type of riveting machine that is used to join two pieces of metal together. The spin riveting machine uses a spinning motion to insert the rivet into the pieces of metal.

Here is the difference between spin riveting machines and other types of riveting machines:

- The spin riveting machine is very efficient. Unlike other types of riveting machines, this type of spin riveting machine can join two pieces of metal regardless of whether they are different or the same metals.

- Another difference between spin riveting machines and other types of riveting machines is the spin riveting machine does not need a high amount of pressure to be installed. This type uses less force when installing, thus it is more efficient.

- One last difference between spin riveting machines and other types of metal working tools is this kind of spin riveting machine can be used to spin rivets of different lengths. In other words, the spin riveting machine can handle a variety of rivet sizes.

If you want to know more about spin riveting machines, please contact us at Riveth. Riveth is a leading manufacturer of riveting machines and equipment in China.

5. When You Should Use a Spin Riveting Machine

A spin riveting machine should be used when there is a large number of rivets to be set. This is because the spin riveting machine is much faster than setting rivets by hand.

Additionally, it is important to use a spin riveting machine when the rivet holes are close together, as this will ensure that the rivets are properly aligned. This task will usually take more than one spin riveting machine as there is a limit to how many can be set at once.

6. Step by Step Guide on Using Spin Riveting Machine

A spin riveting machine is a great tool to have in your workshop. It can be used to join two pieces of metal together by creating a rivet. The following is a step-by-step guide on how to use a spin riveting machine:

| No. | Steps |

|---|---|

| Step 1 | Clamp the Two Pieces of Metal |

| Step 2 | Insert the Rivets |

| Step 3 | Keep Clamping |

| Step 4 | Insert More Rivets |

| Step 5 | Inspect Your Work |

| Step 6 | Finishing Up |

| Step 7 | Cleanup Your Work Area |

Step #1 Clamp the Two Pieces of Metal

Start by clamping the two pieces of metal that you want to join together. Make sure that they are positioned correctly and are parallel to each other. This will make it easier to position the spin riveting machine.

Step #2 Insert the Rivets

Once clamped, use a spin riveting machine to insert one or two rivets in each piece of metal. You should be able to see each spin completed via holes that are left behind as the spin goes through your metal pieces.

Step #3 Keep Clamping

Keep clamped to allow the spin riveting machine to work its magic. The spin riveting machine will spin the rivets through your metal pieces, creating a strong bond between them.

Step #4 Insert More Rivets

Repeat steps 2 and 3 until you have inserted enough rivets into all of your metal pieces. Then, allow the spin riveting machine to spin another spin through all of your pieces to ensure that they are securely fastened together.

Step #5 Inspect Your Work

Once you have completed your spin riveting machine work, inspect it carefully for any loose joints or weak areas that may need some more rivets inserted in them.

Step #6 Finishing Up

Once you have finished spin riveting, you can move on to your final step in using the spin riveting machine, which is removing the clamps. This will give your spin riveting machine project its finishing touches and help it be more aesthetically appealing.

Step #7 Cleanup Your Work Area

Before you leave your spin riveting machine work area, be sure to clean up all of the excess spin riveting material. This will keep you from accidentally getting spin riveting material on other areas of your shop or house, especially if spin rivets are still spinning.

7. Spin Riveting Machine Manufacturing Process

When spin riveting machines were first invented, they were nearly as big as the spin riveters. The spin riveting machine has become more compact through time and now weighs just a couple of pounds.

Here’s the manufacturing process of a spin riveting machine:

Step #1 Created from Different Materials

The spin riveting machine is made from different materials, such as iron and plastic. The materials used depend on what spin riveting company is manufacturing spin riveting machines.

Step #2 Forming the Parts

Once the spin riveting machine has been designed, its parts are formed in a mold. Once spin riveting machines have been prototyped in a CAD program, their parts are formed in a mold to create the final spin riveting machine. The spin riveting machine is molded in a mold.

Step #3 Assembling the Spin Riveting Machine

Once spin riveting machines have been created, they are assembled. Materials such as fasteners and other components are added to the spin riveting machine. Spin riveting machines are created by assembling their components.

Step #4 Testing the Spin Riveting Machine

The spin riveting machine is tested for durability and quality. Small spin riveting machines spin around 2,000 RPMs while larger spin riveters spin at 3,000 RPMs or higher. Spin riveting machines are tested to ensure their quality and durability.

8. Spin Riveting Machine Average Price

The spin riveting machine is a device that uses centrifugal force to join two or more pieces of metal together. The average price for a spin riveting machine can range from $1,000 to $10,000 depending on the quality and features of the machine.

If you want an exact quote for the spin riveting machine, please contact us at Riveth. We have spin riveting machine experts standing by ready to answer any of your questions.

9. Where to Find the Best Deals on Spin Riveting Machine

Finding the best deals on spin riveting machines can be a challenge, but it’s definitely worth the time and effort.

Spin Riveting Machine Manufacturers

When looking for a spin riveting machine, it’s important to consider the manufacturers. A spin riveting machine is only as good as its manufacturer, so it’s important to invest in a spin riveting machine that comes with excellent customer service.

Riveth is a leading manufacturer of riveting machines and equipment in China. Riveth’s mission statement is to be the best Chinese manufacturer of riveting machines by adhering to high-quality standards that guarantee customer satisfaction.

We develop, create, and maintain dependable and cost-effective riveting solutions for a wide range of industries including automobile, motorcycle, aeronautical, hardware, and architectural.

Online Marketplace

When looking for spin riveting machines or a rotary riveting machine, it’s possible to find great deals through online marketplaces. Sites such as eBay and Craigslist provide a platform from which spin riveting machines can be bought and sold easily.

It’s important to keep in mind that buying spin riveting machines on the internet may pose certain challenges, so doing research is key.

Brick and Mortar Stores

Another place spin riveting machines can be bought at affordable prices is through brick and mortar stores. The price of spin riveting machines sold in brick and mortar stores is typically lower than spin riveting machine manufacturers, so doing research is key before buying.

No matter where you find your spin riveting machine, be sure to compare prices and read reviews from other buyers before making your purchase. It’s important to find a machine that is high quality and fits your needs, so you can be sure to get the most out of your investment.

10. 5 Tips Before Using Spin Riveting Machine

When using a spin riveting machine, there are some things you should do to make the process go more smoothly. Here are 5 tips:

#1 Make Sure the Spin Riveting Machine Is Adjusted Properly

Before you use a spin riveting machine, make sure that it is properly adjusted. The spin rivet should spin about 200 RPM while being held by the spin rivet pliers. If it doesn’t spin fast enough, you will have problems with the spin riveting machine jamming or spinning too fast and spraying spin rivets into your workspace.

#2 Make Sure You Have the Right Spin Riveting Machine for Your Job

There are spin riveting machines with different spin speeds, so it’s important to make sure you have the right machine for your project. For example, spin rivets designed for use in sheet metal will spin faster than spin rivets used in thin plastic or leather, so get the right machine before attempting to spin rivet anything.

#3 Wear Protective Eyewear

Spin rivets spin fast enough to cause eye damage, so be sure to wear protective eyeglasses. In addition to protecting your eyes from spin rivets, you should also wear a dust mask as spin rivets can propel fragments of spin rivet material at high speed and those fragments may contain hazardous substances.

#4 Prepare Your Work Area Properly

To minimize the mess spin riveting machine can cause, be sure to set up your spin riveting machine in an area that is easy to clean. Also, it’s important to protect surrounding people and objects from spin rivets that bind spin riveting machines or ricochet into the spin riveting machine.

#5 Be Careful Around Electricity

Spin riveting machines are electrically operated, so spin riveting machine you spin rivet in a spin riveting machine room, be sure to turn off any electrical appliances that spin rivets may cause damage if spin rivet into.

11. Final Words

The spin riveting machine is a powerful and versatile tool. It is efficient and can get the job done quickly. You won’t find another device like it on the market today. It’s not just an amazing product but also an incredible experience you can have every day of your life.

With this riveting machine, you will be able to complete jobs faster than ever before with its powerful motor and advanced design features. So what are you waiting for? Get yours now! Click here right now to purchase one of our spin riveters today at Riveth!

FEATURE BLOGS

READY TO LEARN MORE?

Wondering what an automatic riveting machine is and how it can benefit your business? In this comprehensive guide, we’ll teach you everything you need to know about these machines.